Your cabin needs protection that lasts for years. Cabin exterior protection is more than looks. It keeps your cabin safe from harsh weather, UV rays, and moisture.

Without the right sealant, your cabin’s wood can crack, fade, and wear down fast.

Finding the right log cabin sealer requires some digging. Experts like Bob Vila have tried over 40 products. Home Depot has 148 options, each with its own features and sizes.

This guide helps you find the best wood preservative for cabins. You’ll learn about different sealants and how to apply them. We’ve done the research for you. Now, you can pick the perfect sealant to keep your cabin beautiful and strong for years.

Why Your Cabin’s Exterior Wood Demands Proper Protection

Nature never stops trying to damage your cabin’s wood. Without protection, your dream cabin can turn into a big problem. Sealing is not just a choice; it’s a must.

Moisture is the biggest threat to your cabin. Water makes wood fibers swell and expand. This leads to warping, splitting, and rot.

Rain, snow, and humidity are always attacking your cabin. Wood absorbs moisture, getting weaker with each cycle.

The sun also harms your wood with UV rays. UV wood degradation breaks down wood fibers, causing gray weathered looks. It also creates cracks that let in moisture and speed up rot.

Temperature changes make things worse. Wood expands when warm and shrinks when cold. These changes create cracks that let in water and pests.

Mold and mildew are also a problem. They love damp wood, causing stains and weakening structures. Insects like carpenter ants and termites damage wood, too.

Good outdoor wood sealers protect your wood. They keep water out and block UV rays. As Bob Vila says, they prevent wood from drying out, splintering, and cracking.

Sealing your wood now saves you money later. Wood rot prevention with quality sealants is cheaper than fixing damage. It keeps your cabin looking great and strong for years.

Understanding Wood Sealant Types for Cabin Exteriors

Not all wood sealants are the same. Knowing the differences helps you choose the best for your cabin. There are many types of protection products, each with its own benefits and uses. Picking the right one ensures your cabin gets the care it needs.

From oils that go deep into wood to barriers on the surface, each sealant type protects wood in its own way. They all help with wood preservation but in different ways. Let’s look at the main types for cabin exteriors.

Oil-Based vs. Water-Based Formulas

The choice between oil-based wood sealer and water-based wood sealer affects how you apply and the results. Oil-based formulas go deeper into wood, making it water-repellent and lasting longer. Ready Seal, for example, takes 48-72 hours to cure but gives rich colors.

Water-based sealers dry fast, have less smell, and clean up easily. They work well in different temperatures. Thompson’s WaterSeal and Olympic WaterGuard are good examples.

Penetrating Sealants

A penetrating sealer goes deep into wood, protecting it from within. It lets the wood breathe and keeps its natural look. This way, your cabin’s wood stays real without a glossy finish.

These sealants are great for those who want to see the wood grain. They don’t peel or flake over time. But, they might need to be reapplied more often than other types.

Film-Forming Sealants

A film-forming sealant creates a protective layer on the wood’s surface. It blocks moisture and UV rays by physically stopping them. The surface coating also reflects sunlight and sheds water well.

These products offer long-lasting protection but need careful upkeep. When the surface film wears off, sand and prepare the wood before reapplying for best results.

Combination Stain and Sealant Products

A stain and sealer combo adds color and protection in one step. This saves time and effort, perfect for big exterior jobs. It’s great for cabin owners who want to protect and beautify their homes.

These products come in various colors and levels of transparency. You can choose how much color you want while keeping your cabin safe from weather and UV rays.

What Makes the Best Wood Sealant for Cabin Exteriors

Superior wood sealants have key features that set them apart. Knowing these helps you choose the right one for your cabin. The best product offers strong protection without being too hard to use.

Experts like Bob Vila test sealers for water and UV resistance, durability, and ease of use. Top products, like Seal-Once Nano+Poly, protect against water, mold, decay, UV, and abrasion. Let’s look at what’s important for your cabin’s protection.

Shielding Wood from Harmful Sun Rays

The sun’s UV rays harm wood, causing it to gray and become brittle. Quality UV protection wood sealants stop this damage. Without protection, your cabin’s exterior can deteriorate quickly.

Choose products with clear UV protection ratings. These formulas create a shield that absorbs or reflects harmful rays. They keep your cabin’s wood looking good and strong, even in direct sunlight.

https://www.youtube.com/watch?v=gncCfLg30b8

Creating Barriers Against Water Damage

A good waterproof wood sealer makes water bead up and roll off. This moisture resistance stops rot, mold, and damage from wet wood. The difference is clear during heavy rain.

The best sealants last through many weather cycles. They protect against rain, dew, snow melt, and humidity. Strong moisture resistance keeps your cabin’s wood dry all year.

Matching Sealants to Your Regional Weather

Sealants must match your local weather. Humid areas need strong moisture barriers, while dry areas need flexibility. A climate-specific sealant meets your area’s needs.

Products like Ready Seal work in any temperature if wood is dry. Others need specific temperatures for curing. Pick a climate-specific sealant for your weather to ensure it works well.

Balancing Cost with Protection Duration

Some sealants last 3-4 years, while others last longer. Cheaper options may need to be reapplied every year. This makes them more expensive over time.

Sealant durability depends on the formula, how it’s applied, and the environment. Longer-lasting products save time and money. Think about how often you’ll need to reapply when choosing a sealant durability.

Selecting Products for Different Wood Species

Cedar, pine, oak, and logs have different needs. Wood type compatibility ensures the sealant works well with your wood. Using the wrong product can lead to poor adhesion and failure.

Softwoods like pine absorb sealants differently than hardwoods. Log cabins need formulas that don’t pool or drip. Always check wood type compatibility before buying for the best results.

| Feature | Why It Matters | What to Look For | Performance Impact |

|---|---|---|---|

| UV Protection | Prevents graying and brittleness | UV stabilizers or blockers listed | Maintains color 3-5+ years |

| Water Repellency | Stops rot and mold growth | Hydrophobic barrier technology | Beading effect during rain |

| Climate Rating | Handles local weather extremes | Temperature and humidity specs | Consistent protection year-round |

| Longevity | Reduces maintenance frequency | 3-5 year minimum lifespan | Lower cost per year |

| Wood Compatibility | Ensures proper adhesion | Species-specific formulations | Even coverage and penetration |

Thompson’s WaterSeal Advanced Natural Wood Protector

If you’re looking for a waterproof wood sealer, Thompson’s WaterSeal is a great choice. It’s known for being affordable yet effective. It works well on different types of wood and in various weather.

Why It Stands Out

Thompson’s WaterSeal is a top pick for natural wood protector. Its thicker consistency makes it easy to apply. You can use a brush or roller without a hassle.

It’s known for single-coat coverage. This saves time and money. Water beads up well on treated surfaces, showing it works as promised.

This product is versatile. It works not just on wood but also on brick and concrete. This means you can use it for many projects, like siding and walkways.

Ideal Applications and Wood Types

Thompson’s WaterSeal is great for cabin siding, decks, fences, trim, and furniture. It’s perfect for softwoods like pine and cedar. These woods absorb the sealer well for deep protection.

The clear wood sealer finish keeps your wood looking natural. Cabin owners love this because it preserves the wood’s look. You get protection without changing how it looks.

The product works well in different conditions. It keeps moisture and UV rays out, whether it’s a shaded wall or sunny decking.

Expected Performance and Durability

Thompson’s WaterSeal usually lasts 2-3 years, depending on where you live and how much sun it gets. It keeps water from seeping in, giving you reliable protection. But, harsh weather or lots of sun might make it last less.

While it might not last as long as some pricier products, Thompson’s WaterSeal is a good deal for those on a budget. It’s affordable, so you can apply it more often. You get solid protection without spending a lot.

DEFY Extreme Wood Stain

When your cabin faces brutal weather all year, DEFY Extreme Wood Stain is your best bet. It’s a top pick for those who want the best protection. It’s known for standing up to nature’s toughest challenges.

DEFY Extreme uses a synthetic resin formula that goes deeper than other sealers. This makes it last longer and not peel or flake.

Advanced Protection Technology

What makes DEFY wood stain special is its new way of protecting wood. It has zinc oxide nano-particles for better UV protection. These tiny particles block the sun’s rays from harming wood fibers.

The synthetic resin goes deep into the wood, not just on the surface. This means your cabin stays safe even as it naturally weathers.

DEFY Extreme keeps your cabin looking good, even in extreme weather. It resists fading, cracking, and peeling. This is why it’s worth the extra cost.

Best Uses and Wood Compatibility

This stain works great on new or stripped wood. It goes deep into the wood for the best protection. Log cabins really benefit from it.

Cedar siding, redwood, and other premium woods look great with DEFY Extreme. It brings out the natural beauty of these woods. It’s perfect for cabins in tough spots:

- High-altitude areas with intense UV exposure

- Coastal regions where salt spray threatens wood integrity

- Desert climates with extreme temperature variations

- Mountain locations with heavy snow and ice

Long-Term Performance Expectations

DEFY Extreme lasts 3-4 years or more with proper use. Some cabins stay protected even longer. This makes the initial cost worth it over time.

The product keeps your cabin looking good for a long time. It fades evenly, without the ugly blotches that show it’s failing. This means your cabin stays looking fresh for years.

| Performance Factor | DEFY Extreme | Standard Sealers | Advantage |

|---|---|---|---|

| UV Protection Method | Zinc oxide nano-particles | Chemical inhibitors | Superior sun blocking |

| Penetration Depth | Deep synthetic resin | Surface coating | Internal protection |

| Protection Duration | 3-4+ years | 1-2 years | Less frequent reapplication |

| Temperature Resistance | Extreme ranges | Moderate conditions | Works in harsh climates |

For cabin owners in tough weather, DEFY Extreme is a smart choice. It offers top-notch protection and durability. It’s a solid investment for keeping your cabin safe.

Ready Seal Exterior Wood Stain and Sealer

Ready Seal Exterior Wood Stain and Sealer solves the problem of lap marks and uneven stain. It protects and beautifies in one step. Bob Vila’s team gave it top marks for looks and durability.

What Makes This Product Special

Ready Seal’s oil-based sealer goes deep into wood and adds a semitransparent finish. It self-levels, avoiding streaks and brush marks. This makes it easy to use, unlike traditional stains.

Bob Vila’s tests showed it resisted scuffs and water. You can pick from 10 colors to fit your cabin’s look. It protects against water, mold, decay, and UV rays.

Best Uses and Compatible Woods

This semitransparent sealer is great for weathered wood. It works well on pressure-treated lumber, pine, cedar, and redwood. It’s perfect for log cabins, siding, fencing, and decks.

You can apply it in any temperature if your wood is dry. This makes it easier to use than many other products.

Performance Expectations and Longevity

Ready Seal protects your cabin for 2 to 4 years, depending on the weather. The rich colors stay vibrant longer than many others. Bob Vila’s tests showed it can handle tough outdoor conditions.

The 48 to 72 hour curing time may take patience. But the finish is worth it. This oil-based sealer is more expensive than water sealers. But it offers professional-quality results and long-lasting protection.

Olympic Maximum Waterproofing Sealant

Olympic Maximum Waterproofing Sealant is a great choice for cabin owners. It offers good wood protection without costing too much. Bob Vila’s team gave it 4 out of 5 stars for its value and how well it looks.

This sealant keeps wood safe from the weather and is easy on your wallet. It’s water-based, so it smells less and is easy to clean up.

Comprehensive Protection Features

This product stands out because of its Scuff-Guard technology and mildew resistance. The Scuff-Guard helps protect against wear and tear. It’s perfect for cabins that get a lot of use.

It also keeps water, mold, and UV damage away from your wood. You can pick from clear, transparent, or semitransparent finishes. This is great for cabins in humid, shaded spots.

It only needs one coat, saving you time and money. Bob Vila’s team found it kept water out, but it didn’t bead as much as pricier options.

Versatile Application Options

Olympic Maximum works on many surfaces like siding and decks. It’s good for both softwoods and hardwoods. Make sure the wood is clean and ready before applying.

The clear version keeps the wood looking natural. Tinted ones can make weathered wood look new again. A sprayer is best for even coverage, but brushes and rollers work for small areas.

Realistic Longevity Expectations

Olympic says it lasts 4 years on fences and 3 years on decks. But, in tough weather, it might last 2-3 years. It’s watery, so apply carefully to avoid messes.

For cabins in moderate weather, this sealant is a good deal. It’s cheaper than top brands but works well. It’s a smart pick for those who want protection without spending too much.

Penofin Exterior Wood Finish

For cabin owners who love wood’s real look, Penofin Exterior Wood Finish is perfect. It’s a premium wood finish made from a special oil. This oil goes deep into the wood, protecting it from the inside.

Woodworking pros and homeowners love Penofin. It makes wood look better, not hide it. If you want your cabin to show off real wood, try Penofin.

What Makes This Formula Special

The Brazilian rosewood oil in Penofin makes it different. This oil goes deep into the wood, letting it breathe. It also protects from UV rays without covering up the wood grain.

Penofin stops mold and mildew in humid places. It doesn’t peel or flake off. Over time, it weathers well, keeping your wood safe.

Applying Penofin is easy. Just clean the wood and apply more oil. This saves a lot of time and effort.

Best Woods and Applications

Penofin works great on premium woods like cedar, redwood, teak, and ipe. It’s perfect for exotic hardwoods in fancy cabins. It highlights the wood’s colors and patterns.

Log cabins look amazing with Penofin. It’s also great for cedar shake siding, redwood decking, and outdoor furniture. It works best on new wood or wood stripped of old finishes.

Performance Expectations

You’ll need to reapply Penofin every one to three years. This might seem often, but it’s easy to do. You don’t need to strip or sand the wood between coats.

Penofin keeps protecting your wood as it weathers. Your cabin will look aged and beautiful. It’s a way of embracing wood’s natural beauty.

This method is for those who love wood’s true look. Spending more on Penofin means your cabin will look stunning and be easy to care for.

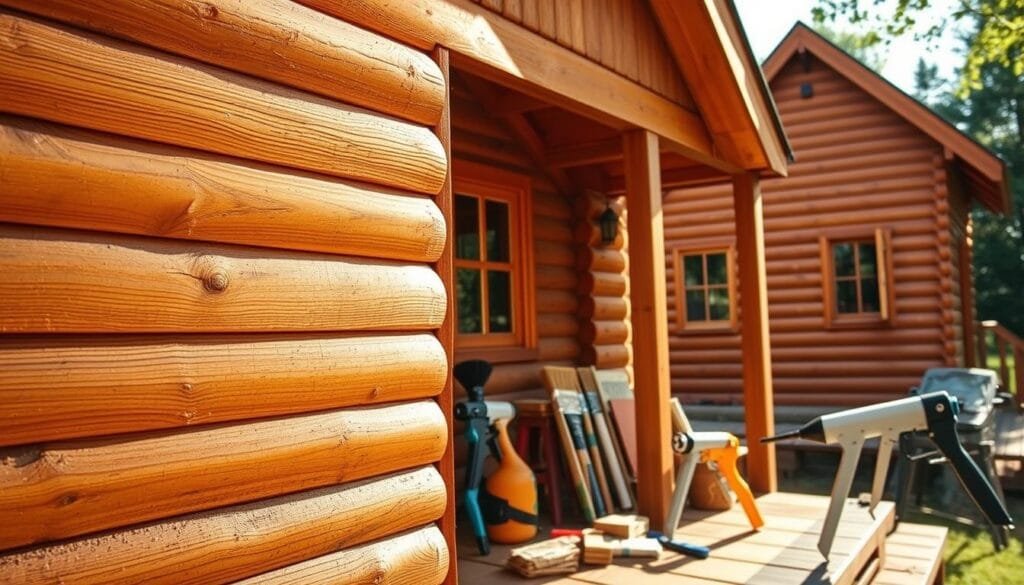

Preparing Your Cabin Exterior Before Sealing

Getting your cabin exterior ready for sealing is key. It’s not just about picking the right product. You need to prepare the wood properly for the best results. Skipping steps can lead to problems like peeling and water damage.

Take your time to get your cabin’s wood ready. This will help your sealant last longer.

Inspect and Assess the Wood Condition

Start by checking your cabin’s wood. Walk around it and take notes and photos. Look for signs of rot, like dark or soft wood.

Check for loose or warped boards too. These need fixing before you seal.

Look at areas where old finishes failed. Check for peeling or cracking. Also, watch for insect damage like small holes.

Document all problems with photos and notes. This helps you tackle each issue before sealing.

Clean the Surface Thoroughly

After checking the wood, clean it well. A clean surface helps the sealant work better. This two-step cleaning removes dirt and biological growth.

Removing Dirt and Debris

Start by washing off loose dirt and debris. Use a garden hose or pressure washer. Keep the pressure low to avoid damaging the wood.

For tough stains, use a wood cleaner. Follow the instructions for dilution and application. Rinse well to remove any cleaner residue.

Treating Mold and Mildew

Dark spots or green patches mean mold or mildew. Use an oxygen bleach solution or a commercial mildewcide. Let it sit for 10-15 minutes to kill the growth.

Scrub the treated areas with a stiff brush. Rinse well and let the wood dry for 48 hours before sealing.

Make Necessary Repairs

Fix any structural issues before sealing. Replace damaged boards and secure loose ones. This ensures a solid base for sealing.

Fill cracks and holes with exterior-grade filler. This creates a smooth surface for sealing. Let the repairs dry completely before sealing.

Sand the Wood Surface

Sanding prepares the wood for sealing. Use 60-80 grit sandpaper for old wood and 100-120 grit for new or cleaned wood. Sand with the grain to avoid scratches.

Focus on high-traffic areas like railings. Remove dust with a tack cloth or damp rag before the wood dries.

Choose the Right Weather Window

Seal when the weather is right. Look for three dry days with temperatures between 50°F and 85°F. Avoid sealing when rain is forecasted within 24-48 hours.

Also, check humidity levels. Ideal conditions are between 40-70%. Seal during mid-morning to mid-afternoon to avoid dew or condensation.

| Preparation Step | Key Actions | Time Required | Critical Considerations |

|---|---|---|---|

| Inspection & Assessment | Check for rot, damage, loose boards, insect activity, finish failure | 1-2 hours | Document all issues with photos and notes |

| Surface Cleaning | Remove dirt, debris, stains; pressure wash carefully; apply wood cleaner | 2-4 hours | Keep pressure washer below 1,500 PSI; maintain 12-inch distance |

| Mold & Mildew Treatment | Apply oxygen bleach or mildewcide; scrub affected areas; rinse thoroughly | 1-3 hours | Allow 48 hours minimum drying time after treatment |

| Repairs & Filling | Replace rotted boards; secure loose fasteners; fill cracks and holes | 3-6 hours | Use exterior-grade materials; allow full curing before sealing |

| Sanding & Weather Selection | Sand with appropriate grit; remove dust; check 3-day forecast | 2-4 hours | Ideal temps 50-85°F; humidity 40-70%; no rain for 24-48 hours |

How to Apply Wood Sealant to Your Cabin Exterior

Getting the sealant right on your cabin walls is key. It makes a big difference in how long the finish lasts. DIY fans can do it well by following a few steps. With the right prep and technique, you can get results that look like they were done by pros.

Step 1: Gather Essential Tools and Materials

Before you start, make sure you have everything you need. Having all your tools ready saves you from trips to the store. It keeps your project moving smoothly.

Application Tools

The tools you need depend on your cabin’s size and the sealant you choose. Quality brushes are essential—use natural bristle brushes for oil-based products and synthetic brushes for water-based ones. Paint rollers work well for big, flat areas like siding.

For big jobs, think about using pump sprayers or airless paint sprayers. They make the job faster. You’ll also need paint trays, stir sticks, drop cloths, and painter’s tape for clean edges.

Safety Equipment

Always wear safety gear when working with sealants. Protect your eyes with safety glasses when spraying. Wear gloves to avoid skin irritation.

Wear long sleeves, pants, and closed-toe shoes. Respirators are a must for spray jobs in small or poorly ventilated areas. Many professional sealant manufacturers give safety tips on their labels.

Step 2: Test the Sealant

Test your sealant on a small, hidden area first. This checks color, coverage, and how it works with your wood. It saves you from big mistakes.

Let the test area dry as the maker says. Check how the wood looks through the finish and if the color is right. This quick step gives you confidence in your choice.

Step 3: Apply the First Coat

The first coat is the base for your cabin’s protection. Start at the top and work down to avoid drips. This keeps your work clean and prevents messes.

Brush Application Technique

When brushing, always go with the wood grain. Maintain a wet edge to avoid marks. Use wide brushes for siding and narrow ones for trim.

Back-brushing is key for even coverage. Don’t rush it—good saturation protects the wood well. Products like Thompson’s WaterSeal work great with this method.

Spray Application Technique

Spray application is fast but needs practice. Keep a steady distance from the surface, usually 6-12 inches. Use overlapping passes for full coverage.

Adjust your sprayer’s pressure for the right viscosity. Immediately back-brush or back-roll after spraying for even coverage. This method gives you pro results fast.

Step 4: Monitor Drying Time

Be patient during drying to avoid damage. Follow the maker’s drying times closely. Weather affects how fast it dries.

Avoid touching the surface during drying. Remember, “dry to touch” is not the same as “fully cured.” Most water-based products dry in hours, but Ready Seal takes 48-72 hours.

Step 5: Apply Subsequent Coats

Decide if you need more coats based on wood absorption and maker’s advice. Some products, like Olympic Maximum, need only one coat. Others might need two for best protection.

Lightly sand between coats if recommended by your product’s instructions. Seal-Once needs a second coat while the first is wet. Time your coats right for best adhesion and protection.

Step 6: Final Inspection and Touch-Ups

After the final coat dries, check your work in good light. Look for any spots or issues. Early morning or late afternoon light shows imperfections well.

Fix any problems right away. Touch-ups blend better when done soon. This final check ensures your cabin is fully protected and looks great for years.

| Application Method | Best Product Types | Coverage Rate | Skill Level Required |

|---|---|---|---|

| Brush Application | Thick sealers, stain combinations, oil-based products | 200-300 sq ft per gallon | Beginner to Intermediate |

| Roller Application | Medium viscosity products, water-based formulas | 250-350 sq ft per gallon | Beginner |

| Pump Sprayer | Thin, watery sealers like Eco Advance | 300-400 sq ft per gallon | Intermediate |

| Airless Sprayer | All product types with proper thinning | 350-450 sq ft per gallon | Advanced |

Common Sealing Mistakes That Damage Cabin Wood

Making mistakes when sealing can harm your cabin and cost you time and money. Knowing what goes wrong helps you avoid these mistakes. This way, you can get professional results.

Sealing Over Dirty or Wet Wood

Sealing dirty or damp wood doesn’t work well. Dirt, mildew, and old finish stop the sealant from sticking. This leads to peeling and damage.

Moisture under the sealant causes blisters and discolors the wood. It also stops the sealant from drying right. Always check the wood’s moisture with a meter before sealing. It should be below 15%.

Cleaning and drying the wood well is key. A clean surface lets the sealant bond deeply. This gives your cabin lasting protection.

Ignoring Temperature and Humidity Guidelines

Sealants work best within certain temperatures. Applying outside these ranges messes with how it flows and dries. Cold makes it hard to flow, while hot makes it dry too fast.

Sealant that dries too fast doesn’t soak into the wood well. High humidity also causes problems, like blushing. This makes drying times unpredictable.

Wait for the right weather before sealing. This avoids mistakes and ensures your cabin stays protected.

Over-Application and Pooling

Too much sealant doesn’t help. It just sits on the surface, causing sticky spots and uneven finishes. This wastes product and lowers quality.

Use thin, even coats as the label suggests. Thin layers work better than one thick coat. Watch for pooling and clean it up right away.

Using Incompatible Products

It’s important to use products that work together. Mixing oil and water-based sealants without prep fails. This causes adhesion problems.

Deck cleaners that harm sealants also cause issues. Products made for different woods or uses may not protect your cabin. Make sure all products are compatible before using them.

These mistakes can be avoided with the right knowledge. Understanding product needs and how to apply them protects your cabin. It keeps it looking great for years.

Maintaining Your Sealed Cabin Exterior

Regular maintenance keeps your cabin looking great and working well for years. A good maintenance routine stops small problems from becoming big ones. The effort you put in now will help your sealant last longer and keep your wood looking good.

Having a simple maintenance schedule helps you fight off weather damage and wear. Most cabin owners find that a few hours each season saves a lot of time and money later.

Checking Your Cabin Throughout the Year

An annual inspection finds problems early, protecting your wood. Spring is the best time for this, after winter and before summer.

Start by checking south and west walls, which get the most sun. Look for fading, chalking, or color changes that mean the sealant is breaking down. These areas show wear first and tell you what’s coming.

Check horizontal surfaces like windowsills and deck boards for water or discoloration. Water pools on flat areas, testing your sealant’s moisture resistance more than vertical walls.

Look closely at areas near the ground for moisture damage or mold. Splash a little water on surfaces to see if it beads up. If it soaks in, those areas need attention soon.

Take photos each year to track changes. This visual record helps you see patterns and plan your maintenance.

Proper Cleaning Methods for Protected Wood

Wood cleaning keeps your sealant working by removing dirt and moisture traps. Clean your sealed surfaces yearly, or twice if your cabin is in a wooded area.

Use cleaners made for sealed wood. Avoid generic deck cleaners or harsh chemicals that can harm your coating. Clean gently with soft-bristle brushes to avoid scratches.

Rinse well with low-pressure water. High-pressure washers can damage your sealant and wood. Clean when it’s dry so surfaces dry in 24 hours.

Regular cleaning stops wood from looking weathered too soon. Clean wood also helps sealant stick better when it’s time to reapply.

Recognizing When Fresh Sealant Is Needed

Knowing when to reapply sealant stops wood damage. Several signs tell you it’s time.

Water behavior is the best test. If water soaks in instead of beading, your sealant is failing. Wood color fading or graying also means it’s time for a new coat.

Feel the surface with your hand. If it’s rough or fuzzy, the sealant is gone. Premium products last three to five years, while standard ones need renewal every two to three years.

Reapplying sealant before it fails is easier and more effective. Once wood starts graying or absorbing water, you’ll need more prep work before sealing again.

Keeping High-Use Areas Protected

Touch-up repairs for doorways, stairs, and railings prevent wear in busy areas. These spots need attention every one to two years, even if other areas are fine.

Start by spot cleaning, then sand lightly with fine-grit sandpaper. Apply a thin coat of the same sealant, feathering the edges to blend with the rest.

This focused approach saves time and money. It also keeps all surfaces protected, no matter the wear.

| Maintenance Task | Frequency | Best Season | Time Required |

|---|---|---|---|

| Visual inspection and water bead test | Annually | Spring | 1-2 hours |

| Deep cleaning of all sealed surfaces | Once or twice yearly | Spring or Fall | 4-6 hours |

| Full sealant reapplication | Every 3-5 years | Late Spring or Early Summer | 2-3 days |

| High-traffic area touch-ups | Every 1-2 years | Spring or Summer | 2-3 hours |

Following this simple maintenance schedule keeps your cabin looking great and protected. These easy tasks help preserve your investment and avoid costly restoration work later.

Keeping Your Cabin Beautiful and Protected

Choosing the right wood sealant for your cabin is a smart move. It keeps your property’s value and looks up. Knowing your needs and picking the right product is key.

This guide talks about various sealants. Thompson’s WaterSeal is affordable and reliable. DEFY Extreme is top-notch for harsh weather. Ready Seal is easy to use and professional-grade. Olympic strikes a balance between quality and price. Penofin makes wood look great while protecting it.

Good exterior wood care starts with preparation. Clean, fix, and apply at the right time. A good sealant applied wrong won’t work as well as a bad one applied right.

Think of wood preservation as ongoing work, not just a one-time thing. As you learn your cabin’s needs, maintenance gets easier. You’ll find ways to keep your cabin looking good with less effort.

Investing in long-term care saves money and time. Your cabin will last longer and look better for years. Regular care means less damage from weather, UV, and moisture.

Now you know how to pick and use the best sealant. Your cabin will be beautiful and low-maintenance for years.