Did you know pressure-treated wood can last over 60 years in harsh conditions? This shows why it’s a great choice for cabins. Let’s see how to use it for your next outdoor project.

Pressure-treated wood has been used in U.S. construction for over a century. It protects against decay and insects. When building a cabin, picking the right materials is key. Loglap cladding is also good for a rustic look, but pressure-treated wood is better at resisting rot.

Building techniques are important for getting the most out of pressure-treated lumber. Knowing its properties and using the right methods can make your cabin last long. Every step in building adds to your cabin’s durability.

Are you ready to build a rot-resistant cabin? Let’s learn about using pressure-treated wood for your dream outdoor space.

Understanding Pressure-Treated Wood

Pressure-treated wood is great for outdoor projects because it lasts long and fights off decay. The process pushes wood preservatives deep into the wood. This creates a shield against moisture, bugs, and fungi.

What is Pressure-Treated Wood?

Pressure-treated wood gets a special treatment. Chemicals are pushed deep into the wood fibers. This makes the wood strong against rot and bugs.

The wood can last up to 40 years, perfect for poles and beams.

Common Treatments and Chemicals

Wood preservatives have changed over time. Before 2003, chromated copper arsenate (CCA) was used but had arsenic. Now, safer options like Alkaline Copper Quaternary (ACQ) and Propiconazole are used. These treatments protect well without the dangers of old preservatives.

| Treatment Type | Usage | Lifespan |

|---|---|---|

| Above-ground | 6+ inches above soil | 10-20 years |

| Ground-contact | In or near soil | 20-40 years |

Advantages

Pressure-treated wood has many benefits for outdoor projects:

- It lasts 20-40 years with care

- It fights off rot, decay, and bugs

- It’s cheaper than natural woods

- It’s good for many outdoor uses

Even though it’s not waterproof, it slows down moisture. This lowers the chance of rot. Wait 6-12 months after treatment to stain or seal for best protection.

Essential Building Considerations

Building a rot-resistant cabin with pressure-treated wood involves many factors. You need to think about the climate, building codes, and how it affects the environment. These elements are key to a successful project.

Climate and Location

The place where you build your cabin matters a lot. Places with lots of rain or high humidity need extra care. Pressure-treated southern yellow pine is strong and fights rot well, perfect for tough weather.

For even more durability, think about using Osage orange or black locust. They can last up to 500 and 100 years, respectively.

Building Codes and Regulations

Following local building rules is very important. These rules tell you what kind of treated wood to use. For example, wood touching the ground needs special treatment.

It’s vital to check and follow these rules. This ensures your cabin is safe and legal.

Environmental Impact

Pressure-treated wood is great against rot but has environmental downsides. It contains chemicals that can harm nature. To lessen this, use natural woods like cedar or redwood for parts that don’t bear weight.

Also, make sure to dispose of treated wood scraps properly. This helps protect our planet.

| Wood Type | Lifespan (Years) | Environmental Impact |

|---|---|---|

| Pressure-treated Pine | 5-10 | Moderate |

| Osage Orange | Up to 500 | Low |

| Black Locust | Up to 100 | Low |

Selecting Pressure-Treated Wood

Choosing the right pressure-treated wood is key for a rot-resistant cabin. The lumber selection process involves looking at wood species, treatment grades, and how to buy.

Wood Species

Different wood species react differently to pressure treatment. Pine, cedar, Douglas fir, and hem-fir are top picks for cabins. Southern Pine is great because it absorbs treatment well. Cedar is natural but costs more.

Grades

Pressure treatment grades show how well the wood works for different uses:

- Above ground: For parts not touching soil

- Ground contact: For posts and landscaping

YellaWood® uses micronized copper preservatives. MicroPro® is certified as an Environmentally Preferable Product.

Purchasing

When buying pressure-treated lumber for your cabin:

- Check end tags for usage recommendations

- Look for kiln-dried (KDAT) products to minimize warping

- Consider the 10-40 year lifespan of properly maintained treated wood

| Wood Type | Treatment | Lifespan | Maintenance |

|---|---|---|---|

| Pressure-treated | Chemical preservatives | 10-40 years | Low |

| Untreated | None | 1-5 years | High |

| Naturally resistant | Natural oils | 15-25 years | Medium |

Remember, pressure-treated wood needs less upkeep than untreated wood. It’s a great choice for a long-lasting cabin.

Tools and Materials

Building a rot-resistant cabin needs the right tools and supplies. Let’s look at what you’ll need for this project.

Essential Building Tools

Working with pressure-treated wood requires reliable tools. Here’s a list of must-haves:

- Circular saw

- Drill and drill bits

- Hammer

- Measuring tape

- Level

- Safety gear (gloves, goggles, dust mask)

Remember, safety is key when working with pressure-treated lumber. Always wear protective gear to avoid chemical exposure.

Rot Resistance Materials

Pressure-treated wood is a top choice for rot-resistant cabins. It can last 40 to 50 years with care. Other options include:

| Material | Advantages | Cost |

|---|---|---|

| Western Cedar | Naturally resistant, attractive appearance | High |

| Redwood | Durable, aesthetically pleasing | High |

| Black Locust | Extremely durable, locally sourced | Moderate |

| White Oak | Strong, resistant to decay | Moderate |

Use stainless steel or hot-dipped galvanized fasteners to prevent corrosion with these materials.

Choosing the right tools and materials will help you build a durable cabin. It will last for decades, standing up to the elements.

Preparing the Site

Getting your site ready is essential for a cabin that lasts. This means checking the land, clearing it, and planning your cabin’s layout.

Assessing the Land

Start by looking over the land carefully. Check for any drainage problems, the soil type, and the terrain. Think about sunlight and wind to place your cabin right.

Clearing and Leveling

After checking the land, clear it of plants and rocks. Remove any trees or shrubs that could get in the way. Make sure the ground is level for a solid base. This helps avoid moisture problems with your wood.

Cabin Layout Planning

Think about your cabin’s design to use pressure-treated wood well. Keep these points in mind:

- Elevate the structure at least 18 inches above grade to protect floor joists

- Use pressure-treated wood for bottom wall plates and mudsills

- Plan for proper ventilation to prevent moisture buildup

- Design the roof with adequate overhang to protect walls from rain

| Component | Recommended Treatment | Minimum Elevation |

|---|---|---|

| Bottom wall plates | Pressure-treated | In contact with concrete |

| Girders (beams) | Pressure-treated | 12 inches above grade |

| Floor joists | Pressure-treated | 18 inches above grade |

By following these steps, you’ll build a strong base for your cabin. This ensures it lasts long and stays sturdy.

Working with Pressure-Treated Wood

Pressure-treated wood has been a key material in U.S. building for over a century. It’s great for making cabins that resist rot. Let’s look at how to work with it well.

Cutting and Shaping

When cutting pressure-treated wood, use sharp tools to avoid splinters. A circular saw with a fine blade is good for straight cuts. For curves, a jigsaw is better. Always double-check your measurements before cutting to save wood.

Handling and Safety

When working with pressure-treated wood, safety is key. Wear gloves, a dust mask, and safety glasses to protect against chemicals. Work in a place with good air flow or outside. Clean your hands well after touching the wood, before eating or drinking.

Fastening Methods

Choosing the right fasteners for pressure-treated wood is vital for lasting results. Use fasteners like hot-dipped galvanized, stainless steel, or other corrosion-resistant types. These protect against the wood’s treatment chemicals. Always pre-drill holes to avoid splitting, mainly at the ends of boards.

| Fastener Type | Best Use | Corrosion Resistance |

|---|---|---|

| Hot-dipped galvanized | General construction | Good |

| Stainless steel | High-moisture areas | Excellent |

| Copper-plated | Light-duty applications | Moderate |

Using the right methods and materials will make your pressure-treated wood structure last for many years. With these tips, you’re set to build a strong, rot-resistant cabin.

Creating a Rot-Resistant Foundation

A strong cabin foundation is key for lasting construction. We’ll look at how to make a rot-resistant base with pressure-treated wood.

Suitable Foundation Types

Concrete foundations are common but expensive and slow. For cabins, pier and beam foundations work well on uneven land. Skid foundations are cheap and don’t need permits. Screw pile foundations are stable against frost and wind.

| Foundation Type | Installation Time | Cost | Adaptability |

|---|---|---|---|

| Pier and Beam | 15 days | $20,000 | High |

| Skid | 2-3 days | Low | Medium |

| Screw Pile | 1-2 days | Medium | High |

Importance of Elevation

Elevating your cabin is vital to avoid rot. Keep it off the ground to prevent moisture issues. Use pressure-treated wood rated for ground contact, with a treatment level of .60 lbs per cubic foot. This ensures your foundation lasts in damp conditions.

Drainage Solutions

Effective drainage is essential for moisture control. Add a layer of rigid foam insulation between OSB sheets for warmth. Use sill sealer as a barrier between concrete and wood. Space floor joists 16 to 24 inches apart for support. These steps help your cabin foundation resist rot for decades.

- Use gravel or crushed stone for better drainage

- Install gutters and downspouts to direct water away

- Slope the ground around the foundation for water runoff

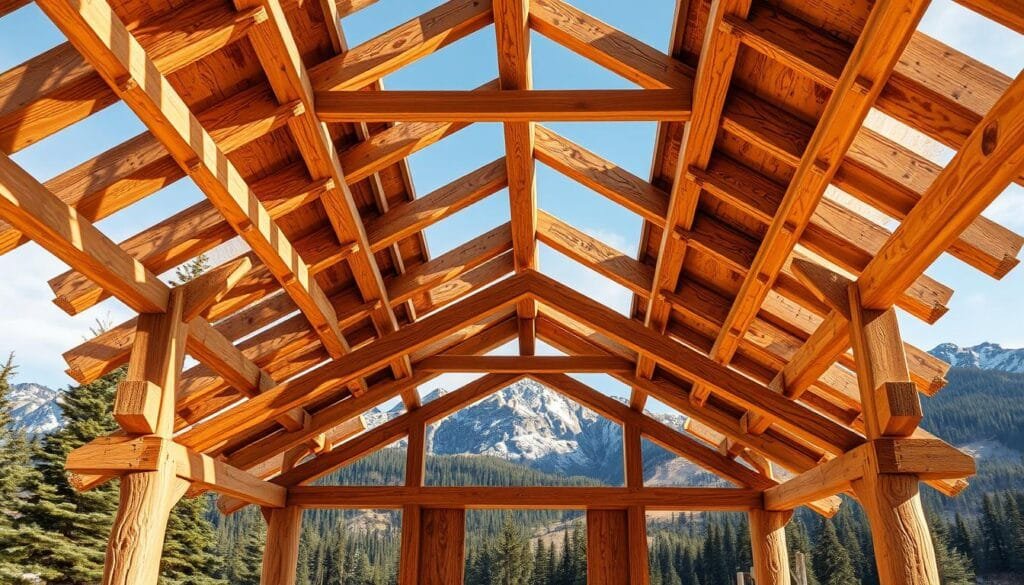

Building the Cabin Structure

Building a strong cabin needs careful planning and action. Key parts include wall framing, roof design, and insulation. Let’s look at these to make sure your cabin lasts for many years.

Wall Framing

The frame of your cabin is its core. Use treated lumber for the bottom plates and where it touches concrete. This stops rot and makes your cabin last longer. Place studs 16 inches apart for strength and support. Make sure to leave space for windows and doors.

Roof Design

The roof is key to keeping your cabin safe from the weather. Pick a design that fits your area’s weather, like a steep roof for snow. Use trusses or rafters for the roof frame. Also, add good ventilation to avoid moisture problems.

Insulation

Good insulation keeps your cabin warm and saves energy. Use spray foam for walls and roof for a tight seal. Fiberglass batts are good for floors. Always put a vapor barrier on the warm side to stop moisture.

| Component | Recommended Material | Benefits |

|---|---|---|

| Wall Framing | Pressure-treated lumber | Rot resistance, longevity |

| Roof Construction | Trusses or rafters | Structural integrity, load distribution |

| Insulation | Spray foam, fiberglass batts | Energy efficiency, moisture control |

By paying attention to these important parts of building a cabin, you’ll make a sturdy and cozy place. It will stand up to time and nature’s challenges.

Finishing and Treatments

The final touches on your pressure-treated wood cabin are key to its look and life. Proper wood finishing boosts its appearance and protects it from the elements.

Staining and Sealing

Timing is everything when staining pressure-treated wood. You can stain as early as 6 weeks after building. Use the ‘sprinkle test’ to see if the wood is ready. If water beads up, wait; if it absorbs, you’re ready.

Clean the wood well before staining and let it dry for 24 hours. Choose from clear, translucent, semi-transparent, semi-solid, or solid stains for your desired look and protection.

Outdoor Paint

Some prefer outdoor paint over staining for pressure-treated wood. Paint offers great protection and color options. Make sure the wood is dry and use exterior paint made for pressure-treated wood.

Remember, paint forms a film that may peel if moisture gets trapped underneath.

Maintenance

Regular maintenance is vital for your cabin’s longevity. Check your cabin annually for wear or damage. Clean the exterior to prevent mold and algae.

Reapply wood preservatives every couple of years to keep your cabin protected. With proper care, your cabin will last for many years.