Your retreat’s structural backbone needs more care than many owners give it. A strong, protected base keeps your cabin stable, dry, and energy-efficient for years.

Moisture is a big threat to log structures. Using below-grade barriers and proper weatherproofing stops water damage and heat loss. Permeable membranes help keep water away from your building, preventing problems.

Different foundations need unique protection plans based on your climate. Whether building new or improving existing structures, the right method saves money on energy. It also avoids costly repairs later.

This isn’t about just filling gaps with materials. You need a detailed system for thermal performance, moisture control, and structure. From protecting foundation insulation with cementitious coatings to installing drainage systems, each step is important.

We’ll make everything easy to follow, so you can do it yourself or talk about it with contractors.

Why Foundation Insulation Matters for Your Cabin

The space under your cabin floor is key to comfort and cost savings. Insulating walls and attics is important, but your foundation plays a big role too. It affects heat loss and moisture issues. Knowing this helps you protect your cabin’s health and performance.

Foundation insulation acts as a shield, working all the time. It keeps your cabin cozy and protects it from the elements. This investment saves you money on repairs and makes your home more enjoyable all year.

Staying Warm and Saving Energy

Walking on a cold floor in winter is not just uncomfortable. It shows your cabin is losing heat through an uninsulated foundation. Energy efficiency starts with the foundation, and an exposed one wastes heat.

Without insulation, drafts near walls and baseboards are common. This makes some rooms cold while others are warm. It strains your HVAC system and makes your home less cozy.

Good foundation insulation stops these cold spots. It keeps warm air in and lets your heating system work better. Your cabin stays warm without constant thermostat changes.

Defending Against Moisture and Structural Damage

Moisture is a big threat to cabin foundations, and moisture control foundation starts with insulation. Water vapor can harm concrete and soil, leading to mold and rot.

Timber insulation is important, but it needs protection. Moisture above 15% in logs can cause serious damage. This can lead to expensive repairs.

Foundation insulation works with waterproofing to fight moisture. It stops condensation and blocks moisture from the ground. This keeps your foundation dry and your timbers healthy.

Proper moisture management prevents shifting foundations and wood damage. It protects your investment by keeping your cabin’s structure strong.

Long-Term Financial Benefits

Foundation insulation saves money in many ways. It cuts down on heating and cooling costs. It also prevents costly repairs and extends your cabin’s life.

Insulation pays for itself in 5 to 10 years through lower bills. In cold climates, savings are even bigger during winter.

Preventing repairs saves thousands of dollars. Moisture damage can cost over $10,000 to fix. Insulation prevents these problems, saving more than it costs.

Your cabin’s value goes up with good foundation work. Buyers see well-maintained foundations as a sign of care. They like lower bills and a solid base.

Energy-efficient homes sell for more. Foundation insulation shows you care about sustainability and saving money. This attracts buyers and investors.

Understanding Common Cabin Foundation Types

Knowing your cabin foundation type is key to choosing the right insulation. Different foundations need different insulation strategies and materials. Before buying insulation or hiring a contractor, identify your foundation type.

The foundation you choose affects everything from materials to cost. Let’s explore the four main types to help you make informed decisions for your cabin’s future.

Concrete Slabs Poured Directly on Ground

A slab foundation is a single layer of concrete on the ground. It’s popular for cabins because it’s simple, affordable, and works well in many climates.

Slab foundations don’t need crawl spaces or basements. The concrete is 4 to 6 inches thick, resting on gravel for drainage. They’re great in areas with high water tables or mild climates.

In cold climates, builders use creative solutions. For example, in Minnesota’s Zone 6a, they use slab foundations with double-stud walls. This design allows foam insulation to cover the walls, creating a solid thermal barrier.

The advantages include lower construction costs, faster installation, and less pest access. But, slabs make it harder to access plumbing and electrical systems later. They also offer no storage space.

Accessible Spaces Between Ground and Floor

A crawl space foundation has a gap between the floor and ground, 18 inches to 4 feet high. It’s a middle ground between slabs and basements.

Crawl spaces give access to plumbing, electrical wiring, and HVAC systems. They’re common in areas with moderate soil or sloping terrain.

This design protects wooden floors from moisture. It also makes repairs easier than slabs. But, crawl spaces need careful moisture control and insulation to prevent problems.

Without proper treatment, crawl spaces can become humid and attract mold and pests. You must decide whether to condition or leave it unconditioned, affecting insulation needs.

Full Underground Living Spaces

A basement foundation adds another floor below ground. These foundations are 7 to 8 feet deep, creating living or storage space.

Basements are best in cold climates where digging is needed. They offer extra space, storage, and easy access to utilities.

Insulating basement walls is challenging due to soil contact. You must choose between interior or exterior insulation, each with its own benefits.

Basements are more expensive due to excavation and waterproofing. But, the extra space is often worth it, even for year-round use.

Elevated Support Column Systems

Pier and post foundations elevate your cabin on columns. They’re great for uneven terrain, floods, or environmental concerns.

Each column supports the cabin’s weight, spaced 6 to 12 feet apart. This design creates an open area underneath.

The benefits include flexibility on challenging sites, reduced excavation, and better flood protection. They’re ideal for steep hillsides or wetlands.

Insulation for pier foundations focuses on the floor system. You’ll also need skirting to close the space underneath while allowing ventilation. This prevents drafts in your cabin floor.

| Foundation Type | Best Climate Use | Insulation Focus Area | Cost Level | Main Advantage |

|---|---|---|---|---|

| Slab-on-Grade | Mild to moderate climates, high water tables | Perimeter and under-slab | Low to Moderate | Simple, fast construction |

| Crawl Space | Moderate climates, variable terrain | Floor joists or wall systems | Moderate | Utility access and repairs |

| Full Basement | Cold climates below frost line | Below-grade walls (interior/exterior) | High | Maximum usable space |

| Pier and Post | All climates, challenging terrain | Floor system and skirting | Moderate to High | Site flexibility and flood protection |

Understanding your cabin foundation type is essential for choosing the right insulation. Each foundation type offers unique opportunities and challenges for energy efficiency and comfort.

Climate Zones and Their Impact on Foundation Insulation

Building your cabin in the right place is key for foundation insulation. The U.S. has different climate zones, from tropical to arctic. Knowing your zone helps save money and avoid mistakes.

The Department of Energy has seven climate zones, from 1 to 7. Zone 1 is warm, like southern Florida. Zone 7 is cold, like northern Minnesota and Alaska. Your cabin’s location affects how much insulation you need and what materials to use.

Building codes set R-value requirements based on your zone. These rules help keep your cabin comfortable and prevent damage from extreme temperatures. Let’s look at what each zone means for your foundation insulation.

Freezing Temperatures and Deep Frost Lines

Zones 5, 6, and 7 face serious cold. Your cabin needs strong insulation to fight frost heave and ice damage. This keeps your energy bills down.

In these zones, you need R-value requirements of R-15 to R-25. The colder your zone, the higher your R-value should be. Zone 7 cabins might need R-25 or more, while Zone 5 can get by with R-15.

Minnesota is a good example. In Zone 6a, frost can go up to four feet deep. Builders use 4-inch rigid foam insulation around slab foundations. This foam goes below the frost line and is covered with aluminum flashing.

Continuous insulation is key in these zones. Gaps in insulation let cold in, causing frost heave. The freeze-thaw cycle damages your foundation over time.

Here are important tips for cold climate foundations:

- Install insulation to the frost line depth

- Use closed-cell foam that won’t absorb moisture

- Protect exterior insulation with durable flashing or protective board

- Ensure continuous coverage with no gaps or thermal bridges

- Consider insulating under the entire slab in Zone 6 and 7

Balanced Protection for Variable Weather

Zones 3 and 4 have moderate climates. Winters are cold but not extreme. You’ll need R-value requirements between R-10 and R-15.

In these zones, you can use less insulation and get good results. A 2-inch to 3-inch layer of rigid foam is often enough. You don’t need to insulate as deeply as colder zones.

Insulation in these areas helps with heating and cooling. Your cabin will be comfortable all year. This makes insulation a smart investment.

| Climate Zone | Minimum R-Value | Typical Insulation Thickness | Frost Depth Range |

|---|---|---|---|

| Zones 5-7 (Cold) | R-15 to R-25 | 3 to 5 inches foam | 30 to 60+ inches |

| Zones 3-4 (Moderate) | R-10 to R-15 | 2 to 3 inches foam | 12 to 30 inches |

| Zones 1-2 (Mild) | R-5 to R-10 | 1 to 2 inches foam | 0 to 12 inches |

Moderate zones offer more flexibility. You can use spray foam or rigid board insulation. But don’t forget moisture barriers, as rainfall can harm foundations.

Don’t Skip Insulation in Warm Regions

Zones 1 and 2 are the warmest parts of the U.S. You might think insulation isn’t needed, but it’s a must. It keeps your cabin comfortable and controls moisture.

In these zones, you’ll need R-value requirements of R-5 to R-10. Insulation helps maintain indoor temperatures and reduces cooling costs. It also acts as a moisture barrier, which is important in humid areas.

Insulation in warm climates also keeps pests out. Termites and other insects are active year-round. A well-insulated foundation makes it harder for them to get to your cabin’s wood.

Energy efficiency is important everywhere. Even in warm climates, your air conditioning works hard. Insulation keeps cool air in and reduces your HVAC’s workload. This saves you money and makes your cabin more comfortable.

Check the Department of Energy’s climate zone maps to find your location. Many counties publish frost depth and insulation requirements online. Your local building department can give you exact requirements for your area.

Best Insulation Materials for Cabin Foundations

Foundation insulation comes in several types, each with its own strengths. They handle moisture, provide thermal performance, and last a long time. Knowing the pros and cons helps you pick the best for your cabin.

The main types are rigid foam boards, spray foam, and fiberglass batts. Each works differently in moist environments.

Rigid Foam Insulation Options

Rigid foam insulation is the top choice for cabin foundations. It resists moisture, keeps its R-value, and withstands soil pressure. It’s also easy to cut and install, making DIY projects simpler.

There are three types of rigid foam boards. Each has its own performance, cost, and use. Let’s look at each one.

Extruded Polystyrene (XPS)

XPS insulation is the pink or blue foam you see at stores. It has an R-value of about R-5 per inch. It’s great for below-grade use because it resists moisture well.

XPS also has strong compressive strength. It won’t crush under soil or concrete. It’s perfect for exterior walls and under-slab areas. But, it’s more expensive.

EPS is the white beadboard foam that’s cheaper than XPS. It has an R-value of about R-4 per inch. You can spot EPS by its bead structure.

EPS absorbs a bit more moisture than XPS. But it’s better than fiberglass. It’s good for larger projects where cost is a concern. Use it with waterproofing for best results.

Polyisocyanurate Boards

Polyisocyanurate (polyiso) has the highest R-value at R-6 to R-7 per inch. But, it loses performance in cold temperatures. It’s best for interior walls or warmer climates.

For cold regions, use XPS or EPS for exterior walls. Save polyiso for above-grade walls where it excels.

| Foam Type | R-Value Per Inch | Moisture Resistance | Best Foundation Use | Cost Level |

|---|---|---|---|---|

| XPS | R-5 | Excellent | Exterior walls, under-slab | Higher |

| EPS | R-4 | Very Good | All below-grade applications | Lower |

| Polyiso | R-6 to R-7 | Good (but temperature-sensitive) | Interior basement walls | Moderate |

Spray Foam Insulation

Spray foam creates a seamless barrier that insulates and seals. Closed-cell spray foam is best for foundations. It has an R-value of R-6 to R-7 per inch and resists moisture well.

The biggest plus is its complete coverage without gaps. It sticks to walls, stops air leaks, and seals moisture. It’s great for irregular surfaces or areas with many penetrations.

The downside? It needs a pro to install, and it’s more expensive than rigid foam. Open-cell spray foam is cheaper but absorbs moisture. Closed-cell spray foam is worth it for basement walls if you can afford it.

Fiberglass and Mineral Wool

Fiberglass and mineral wool batts are good for walls and attics but not foundations. They absorb moisture, lose value when wet, and can grow mold.

But, they’re okay for crawl spaces if they stay dry. They’re also good for above-grade parts of pier foundations.

If using fiberglass, put a vapor barrier on the warm side and ensure good drainage. Never use it in direct contact with the ground or on exterior below-grade walls. The cost savings aren’t worth the problems.

Choose insulation based on where it will go, your climate, and budget. Rigid foam boards are the best choice for most cabin foundations.

Insulating a Cabin Foundation with Slab-on-Grade

Building a cabin with a slab-on-grade foundation starts before pouring concrete. This foundation type combines your floor and foundation into one. Proper slab insulation is key for energy efficiency and comfort. It keeps your cabin warm and prevents moisture damage.

Insulation involves several steps. Each step builds on the last to create a complete barrier. Let’s explore the process from start to finish.

Preparing the Site and Ground

A solid foundation begins with ground preparation. Start by digging to the right depth and leveling the soil. Remove any organic material or debris that could cause settling.

Next, add a granular base layer of crushed stone or gravel, 4 to 6 inches thick. This layer drains water, prevents moisture wicking, and supports your insulation and concrete slab. Compact it well to avoid settling.

Make sure the area around your cabin slopes away from it. This directs water away from your foundation. Use a level to check the slope.

Installing Perimeter Insulation

The edges of your slab lose the most heat. Perimeter insulation is vital for keeping your cabin warm. Install vertical rigid foam boards around the slab edges before pouring concrete.

In cold climates like Minnesota Zone 6a, use 4-inch thick rigid foam for the perimeter. The insulation should go down to or below the frost line. This prevents frost heaving and saves energy.

Focus on corners and joints where foam pieces meet. Stagger the joints and seal them with foam-safe tape or caulk. Some builders cantilever the cabin walls to sit flush with the foam for a clean look.

Protect your perimeter insulation from damage and UV rays with durable flashing. Use heavy gauge painted aluminum flashing. Nail it to your wall sheathing and extend it below the backfill level.

| Climate Zone | Recommended Foam Thickness | Minimum Depth Below Grade | R-Value Target |

|---|---|---|---|

| Zones 1-2 (Mild) | 2 inches | 12-18 inches | R-10 |

| Zones 3-4 (Moderate) | 3 inches | 24-36 inches | R-15 |

| Zones 5-7 (Cold) | 4 inches | 48-60 inches | R-20 |

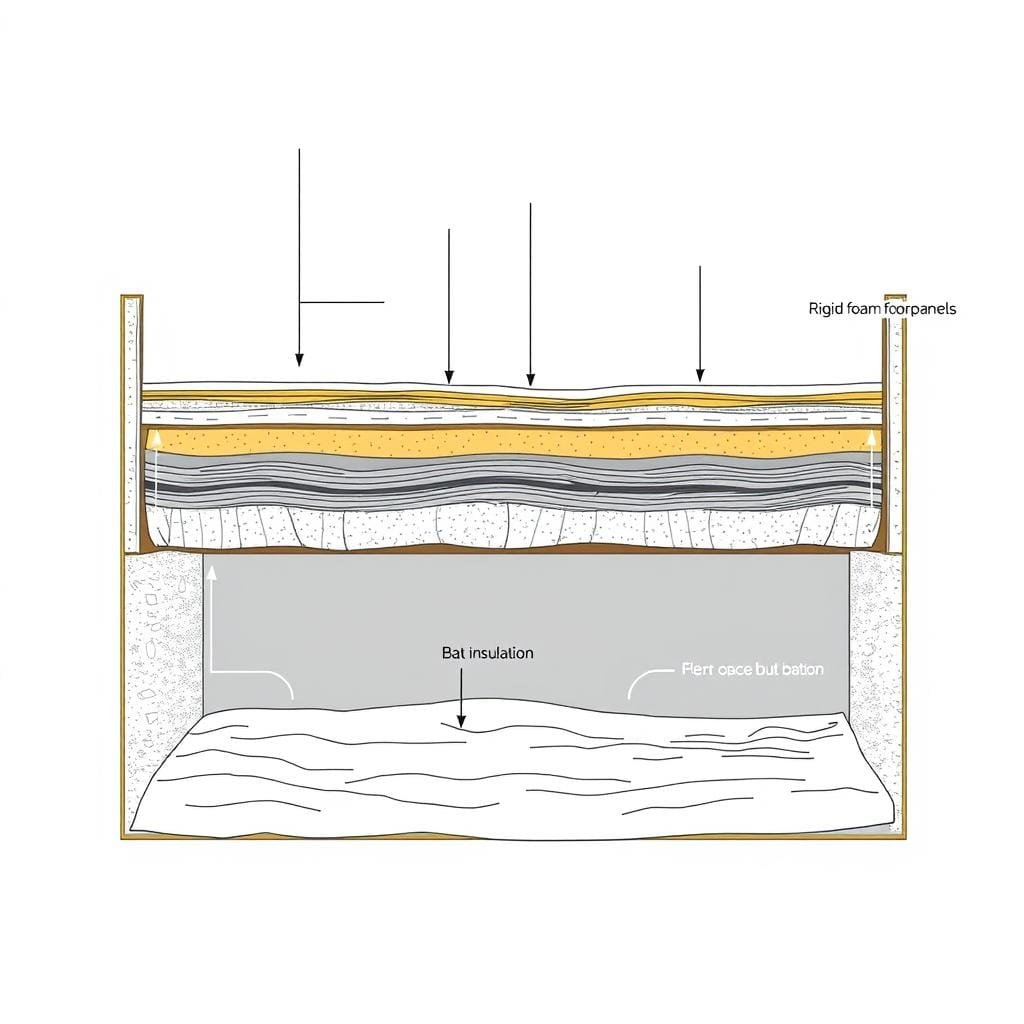

Under-Slab Insulation Techniques

Under-slab insulation stops heat loss through the entire floor. This horizontal layer of rigid foam sits on your gravel base and under your concrete slab. It’s essential in cold climates for energy efficiency.

Choose rigid foam boards that can handle concrete’s compressive load. Use XPS or EPS foam. The thickness depends on your climate, with colder areas needing more.

Install the foam boards in a staggered pattern to avoid continuous joints. Tape all seams with compatible tape to prevent concrete from seeping. Ensure the foam covers the entire slab area without gaps.

Vapor Barrier Installation

The vapor barrier is your last line of defense against moisture. It prevents mold, rot, and structural damage. Never skip this step, no matter the climate.

Use a minimum 6-mil polyethylene sheet, but 10-mil is better. Lay it over your under-slab insulation, covering the whole area. Overlap seams by at least 12 inches and seal them with construction tape.

Extend the polyethylene sheet up the inside face of your perimeter insulation. This creates a continuous barrier. Be careful not to puncture the barrier during concrete placement.

Some builders add a thin layer of sand over the vapor barrier to protect it during concrete placement. This extra step is cheap but valuable. Your system is now ready for concrete.

How to Insulate Crawl Space Foundations

Many cabin owners overlook the importance of crawl space insulation. It keeps your cabin comfortable and saves energy. This area under your floor acts as a buffer against cold ground.

Crawl spaces face moisture, heat loss, and air leaks. Modern science offers solutions to these problems. The right insulation makes a big difference in your cabin’s performance.

Conditioned vs. Unconditioned Crawl Spaces

Choosing between a conditioned crawl space or the traditional unconditioned one is key. This choice affects your insulation strategy. It’s important to understand the differences.

Unconditioned crawl spaces have foundation vents for air circulation. Insulation goes between floor joists, keeping the space cold. This seems logical, but it has its drawbacks.

Those vents let humid air in during summer, causing moisture problems. In winter, they let cold air under your floor, making rooms feel chilly.

A conditioned crawl space seals vents and insulates walls instead of floors. Research shows this method controls moisture better, saves energy, and protects structures longer.

The conditioned approach keeps the crawl space warm and dry all year. Your HVAC system conditions the space, preventing temperature swings and moisture issues.

If your cabin has an unconditioned crawl space that works, you might not need to change it. But for new builds or major renovations, the conditioned approach is worth considering.

Insulating Crawl Space Walls

With the conditioned approach, insulating foundation walls is key. This creates a thermal envelope that includes the crawl space. The process requires attention to detail but offers great results.

Insulate from the top of the foundation wall down to two feet below ground. This protects against heat loss and frost damage. In colder areas, deeper insulation is even better.

Attaching Rigid Foam to Foundation Walls

Rigid foam boards are best for crawl space wall insulation. They resist moisture and provide good R-value in a thin form. Two to four inches of foam meets most climate zone codes.

Clean the foundation walls first. Remove dirt, old paint, and mineral deposits. The surface should be clean for good adhesion.

Apply foam-compatible adhesive to the back of each board. Press the panel firmly against the wall for 30 seconds. Use mechanical fasteners for extra security.

Cut boards to fit around obstacles. Fill gaps wider than a quarter inch with spray foam. These gaps can cause air leaks if not sealed.

Sealing Rim Joists

The rim joist area is a big source of heat loss. Sealing it is critical. Rim joist sealing should be a top priority.

You can use spray foam for a tight seal. A professional can spray foam along the entire rim joist. This creates an airtight barrier.

If you’re doing it yourself, cut rigid foam boards to fit between joists. Seal edges with spray foam to prevent air leaks.

Floor Insulation Between Joists

In unconditioned crawl spaces, insulating between joists is standard. This creates a thermal barrier under your living space. The crawl space stays cold.

Fiberglass batts fit standard joist spacing. Choose batts with a facing for the heated space above. Install them snugly against the subfloor.

Support insulation with wire supports. These hold batts in place without compressing them. Space supports every 18 to 24 inches. Compressed insulation loses R-value.

Seal gaps in the subfloor and around pipes before installing batts. Air leaks carry heat away, making insulation less effective.

Ground Vapor Barriers and Encapsulation

Controlling ground moisture is essential, whether your crawl space is conditioned or unconditioned. A ground vapor barrier protects your investment.

Crawl space encapsulation involves covering the floor with heavy-duty polyethylene sheeting. Use at least 6-mil thickness. Thicker materials offer better durability.

Remove debris and sharp rocks from the floor. A smooth surface prevents punctures. You don’t need a level surface, but clear away obstacles.

Roll out the sheeting across the floor. Overlap seams by at least 12 inches and tape them. Seal every seam—this is a continuous barrier.

Extend the barrier up the walls by 6 to 12 inches. Attach it securely with fasteners or termination bars. Seal around piers and posts with tape or mastic.

In conditioned crawl spaces, some builders install a dehumidifier. This keeps humidity below 60 percent, protecting against moisture problems.

Wall insulation, air sealing, and a vapor barrier transform your crawl space. Your cabin will be more comfortable, energy bills will drop, and the structure will last longer. Doing this work right pays off for decades.

Insulating Full Basement Foundations

Insulating a full basement foundation turns cold, damp space into a cozy, energy-saving area. Full basements are great for adding living space, storage, or mechanical rooms. The key is to pick the right insulation to protect your investment and keep moisture away.

Choosing between exterior foundation insulation and interior basement insulation is a big decision. Each method has its own benefits and challenges that affect performance and cost. Knowing these differences helps you make the best choice for your situation.

Choosing Between Inside and Outside Approaches

The debate between exterior foundation insulation and interior basement insulation centers on thermal performance versus accessibility. Exterior insulation is better because it keeps the foundation warm and dry. This stops thermal bridging and protects your waterproofing from extreme temperatures.

Outside insulation also shields the foundation from freeze-thaw cycles that can crack concrete. The foundation mass stays within your building envelope, helping stabilize indoor temperatures. This is the best option for new construction or major renovations where you can access the exterior walls.

Interior approaches are popular for existing cabins. You can install basement insulation from inside without excavation, which saves money and reduces disruption. The work can be done regardless of weather, and you keep easier access for future changes or repairs.

But, interior insulation leaves the foundation exposed to temperature swings. You must manage moisture carefully to prevent condensation between the cold concrete and warm interior finishes. When done right with proper vapor control, interior systems work well and cost less than exterior alternatives.

Installing Insulation on the Outside

Exterior foundation insulation starts with proper waterproofing. This order is key—you must apply waterproofing membranes directly to clean foundation walls before adding insulation. Water-based spray-on waterproofing products or sheet membranes create the critical moisture barrier.

After waterproofing cures, you can attach rigid foam boards vertically to the foundation. XPS insulation boards work well because they resist moisture and maintain R-value even when damp. These boards usually come in 2-inch or thicker panels that you secure with specialized adhesive or mechanical fasteners designed for below-grade use.

A dimple mat drainage system often goes over the insulation to channel any water downward to your footer drains. This three-layer system—waterproofing, insulation, and drainage—provides complete protection. For those interested in foam-free insulated foundations, alternative approaches exist that use mineral wool or other materials.

The above-grade portion of your exterior foam needs protection from sunlight, physical damage, and pests. Several protective coatings work well for this purpose:

- Cementitious stucco applied directly over foam with mesh reinforcement

- Acrylic coatings that create a tough, weather-resistant surface

- Cement backerboard panels secured to the foundation above the foam

- Pressure-treated plywood for a simple, economical solution

Backfilling requires care to avoid damaging your new insulation. Use clean fill without sharp rocks, and compact in thin layers. Many contractors place a protective board over the foam during backfilling for extra insurance.

Interior Wall Insulation Techniques

Interior basement wall insulation methods vary based on your finishing plans and moisture conditions. The simplest approach attaches rigid foam boards directly to foundation walls using construction adhesive. You then build a framed wall in front of the foam to support drywall or other finishes.

This creates a continuous insulation layer that minimizes thermal bridging while keeping the vapor barrier on the warm side of the assembly. Rigid foam products like XPS or polyisocyanurate (polyiso) provide excellent R-values per inch. You’ll need at least R-10 in moderate climates and R-15 or higher in cold regions.

Framed wall systems offer more flexibility for running electrical wiring and plumbing. You can build standard 2×4 walls against the foundation, then fill the cavities with spray foam insulation for maximum performance. Closed-cell spray foam acts as both insulation and vapor barrier, sealing all the gaps and irregularities in the concrete.

Traditional batt insulation works in framed basement walls, but requires careful vapor barrier installation. You must place a continuous vapor retarder on the warm side of the insulation to prevent moisture from reaching the cold foundation. Any gaps or tears in this barrier can lead to condensation and mold growth.

Never install vapor-permeable insulation directly against cold foundation walls without a proper barrier system. This creates ideal conditions for moisture accumulation. The rule remains consistent: waterproofing goes on first from the outside, and vapor control happens on the warm side of interior insulation.

Solving the Thermal Bridge Problem

Thermal bridging occurs when heat bypasses your insulation through more conductive materials like wood studs or steel framing. In basement walls, these bridges can reduce your effective insulation value by 20-40%. A wall rated at R-19 might perform closer to R-12 because of framing thermal bridges.

The most effective solution uses continuous rigid foam under or outside your framing system. This foam layer intercepts heat flow through the studs before it reaches the cold foundation. Even a thin layer of continuous foam significantly improves overall wall performance.

Staggered stud walls offer another approach that reduces thermal bridging considerably. You build two separate stud walls with a gap between them, offset so studs don’t align. This breaks the direct thermal path while providing excellent insulation depth. The technique works well in cold climates where maximum R-value matters.

Advanced framing techniques also help by reducing the amount of wood in the wall. Using 24-inch stud spacing instead of 16-inch spacing cuts thermal bridges by one-third while maintaining structural integrity. Combined with proper insulation materials, these strategies create high-performance basement walls.

| Insulation Approach | Thermal Performance | Moisture Protection | Cost Level | Best Application |

|---|---|---|---|---|

| Exterior Rigid Foam | Excellent (no thermal bridges) | Superior (foundation stays warm) | High | New construction, major renovations |

| Interior Rigid Foam | Very Good (minimal bridges) | Good (requires careful detailing) | Moderate | Retrofits, finished basements |

| Interior Spray Foam | Excellent (seals gaps) | Very Good (acts as vapor barrier) | Moderate-High | Irregular walls, maximum sealing |

| Interior Batt + Frame | Good (higher thermal bridging) | Fair (requires perfect vapor barrier) | Low-Moderate | Budget-conscious projects |

For most cabin owners doing retrofit work, interior insulation approaches are often chosen. These methods work well when installed correctly with attention to moisture management. But, if you’re building new or doing extensive foundation work, consider the long-term benefits of exterior insulation despite higher upfront costs.

Properly insulated basement foundations provide comfortable, usable space that adds tremendous value to your cabin. Whether you choose exterior or interior methods, focus on continuous insulation layers, effective moisture control, and minimizing thermal bridges for the best results.

Protecting Pier and Post Foundations

When your cabin sits on piers or posts, keeping it warm and dry is key. Unlike solid foundations, these systems leave an open area under your cabin. This area is exposed to wind, weather, and critters.

Pier foundation insulation offers several solutions. You can insulate between piers, add foundation skirting, or focus on the floor system. Many cabin owners use all three methods for the best results.

Creating an Insulated Perimeter

Building an insulated barrier around your piers creates a protected area under your cabin. This is great for cold climates where frost and frozen pipes are a concern. It’s like building a frost wall or pony wall to seal off the space.

Start by framing short walls between each pier with treated lumber. These walls should be 12 to 24 inches tall. Then, attach rigid foam insulation panels to the framing. This insulation is great for blocking wind and keeping heat in.

Install the foam boards between the framing, securing them with adhesive and fasteners. Seal all gaps and seams with spray foam to prevent air leaks. This creates a continuous barrier that keeps your cabin warm.

Even with insulated walls, you’ll need ventilation to prevent moisture buildup. Install screened vents at opposite ends of the perimeter. This allows air to circulate while keeping pests out. In very cold climates, use closeable vents that you adjust seasonally.

Installing Protective Skirting Systems

Foundation skirting is a good option for existing cabins. It blocks wind, improves appearance, and adds thermal protection without major construction. It also helps prevent pipes and utilities under your cabin from freezing in winter.

Several skirting materials work well for insulation:

- Vinyl skirting with foam backing: Lightweight, easy to install, and comes in various colors

- Cement board with rigid foam: More durable, great for harsh weather and areas with falling branches

- Treated plywood with insulation: Budget-friendly, can be painted or stained to match your cabin

- Composite materials: Resists rot and pests, offers moderate insulation

Install your chosen skirting material around the entire perimeter. Attach it securely to the piers and floor framing. Behind the skirting, add at least one inch of rigid foam insulation for thermal protection. Two inches is even better in colder zones.

Never completely seal the skirted area. You must include ventilation openings to allow moisture to escape. Space these vents around the perimeter, ideally on opposing sides for cross-ventilation. Cover all openings with hardware cloth or metal screening to prevent insects and rodents.

For log cabins in harsh conditions, reinforced skirting systems protect against freezing, thawing cycles, strong winds, and physical damage. Consider adding a protective barrier like metal flashing at the top edge where skirting meets your cabin to shed water effectively.

Insulating the Floor System

The most important insulation for any pier foundation is in the floor system. This is your primary defense against cold floors and heat loss. Without proper floor system insulation, even the best perimeter strategies won’t keep your cabin comfortable.

You have two main insulation options for floor systems:

Batt insulation between joists is the traditional approach. Use unfaced fiberglass or mineral wool batts sized to fit snugly between your floor joists. Install them from below, pressing them up against the subfloor. The challenge is holding them in place—gravity wants to pull them down over time.

Support your batt insulation with one of these methods: wire mesh or chicken wire stapled across the bottom of joists, wood strapping installed perpendicular to joists every 16 to 24 inches, or rigid boards cut to fit between joists as a holding system. Whatever support method you choose, make sure the insulation stays in full contact with the subfloor above without compression.

Rigid foam boards offer an alternative that’s good in moisture-prone areas. Cut foam panels to fit between joists and secure them with construction adhesive and fasteners. Foam doesn’t absorb water like fiberglass and provides a higher R-value per inch of thickness.

Your floor insulation must be protected from weather and pests. Exposed insulation deteriorates quickly from moisture, UV rays, and animals looking for nesting material. Cover the entire underside with a durable material like house wrap, rigid panels, or even treated plywood in areas with severe weather.

| Insulation Strategy | Best Climate Zones | Difficulty Level | Cost Range |

|---|---|---|---|

| Between-Pier Walls | Cold (Zones 5-7) | Moderate to High | $$-$$$ |

| Insulated Skirting | All Zones | Low to Moderate | $-$$ |

| Floor System Insulation | All Zones | Moderate | $$ |

| Combined Approach | Cold to Moderate (Zones 3-7) | Moderate to High | $$-$$$ |

Pay special attention to rim joists and band joists where the floor system meets the piers. These areas are notorious for air leaks and thermal bridging. Seal them thoroughly with spray foam before installing your floor insulation. This extra step makes a noticeable difference in comfort and energy bills.

Remember that pier foundations face unique challenges from wind-driven rain, snow accumulation, and temperature extremes. Your insulation system needs to handle these conditions year after year. Invest in quality materials and proper installation techniques now, and you’ll enjoy a warmer, more efficient cabin for decades to come.

Waterproofing and Drainage Protection Strategies

Even the most expertly insulated foundation can fail if water gets through. Waterproofing and drainage systems work together with insulation to protect your foundation. Without proper water management, moisture can cause foundation shifting and damage to insulation, leading to costly repairs.

Think of waterproofing as your cabin’s first defense against moisture. The strategies you use now will help keep your foundation dry and stable for years. Every part of your water protection system works together to keep your cabin safe.

Applying Protective Membranes

Foundation waterproofing membranes act as a barrier between your foundation walls and the soil. These coatings prevent water from getting through while allowing the foundation to breathe. The right membrane depends on your climate, soil, and foundation type.

Liquid-applied membranes are versatile for complex shapes and retrofitting. You brush or roll these coatings onto foundation walls, creating a seamless barrier. They work well for irregular surfaces and need proper surface prep for adhesion.

Peel-and-stick membranes offer reliable protection with easy installation. These self-adhesive sheets bond to foundation walls, overlapping at seams for continuous coverage. They’re great for new construction where you can apply them before backfilling.

Spray-applied membranes cover large areas quickly. Contractors use special equipment to coat walls evenly, creating a durable waterproof layer. This method works well on both vertical and horizontal surfaces.

The key to effective waterproofing is using permeable membranes that move water down to drainage systems. This prevents moisture problems that can cause foundation shifting and damage. Always apply waterproofing before installing exterior insulation in below-grade applications.

Installing Underground Water Management

Drainage systems are a critical second layer of protection. They channel water away before it can saturate the soil around your cabin. Even on slopes, proper drainage prevents water from following the foundation line. French drains are your underground defense against water accumulation.

A good French drain system has perforated pipes at the footing level, surrounding your foundation. The pipes sit in a gravel bed wrapped with filter fabric to prevent clogging. Water seeps through the gravel, enters the pipes, and flows away from your foundation.

Here’s what makes French drains effective:

- Strategic placement at the lowest point of your foundation where water naturally collects

- Continuous slope of at least 1% gradient to ensure water flows away without pooling

- Clean gravel surrounding the pipes that allows rapid water movement while providing structural support

- Filter fabric that separates soil from gravel, maintaining long-term drainage capacity

The gravel bed extends 6-12 inches above and around the pipe, creating space for water collection. This drainage layer works with your waterproofing membrane to catch and direct water away from your foundation.

Position your drainage outlet carefully to ensure water discharges far from your cabin. The system only works if water can exit freely, not backing up during heavy rainfall. Consider connecting multiple drain lines to a common outlet for maximum efficiency.

Creating Positive Slope Conditions

Foundation grading is a simple yet often overlooked protection strategy. Proper grading ensures water flows away from your foundation, preventing moisture problems. This approach stops many issues before they start.

The standard for foundation grading is to slope the ground away from your cabin at least 6 inches over the first 10 feet. This creates positive drainage that moves water away naturally. Steeper slopes work even better, which is great for areas with heavy rainfall or snowmelt.

Maintaining proper grading requires regular attention to several key areas:

- Check for settling or erosion near your foundation that creates low spots where water collects

- Add soil as needed to restore positive slope, using clay-rich soil that compacts well

- Monitor areas where landscaping, sidewalks, or driveways might redirect water toward your foundation

- Ensure downspout discharge points maintain proper elevation relative to surrounding grade

Pay special attention to foundation grading after heavy rains or spring thaw. These conditions reveal problem areas where water pools or flows incorrectly. Fixing grading issues early prevents moisture infiltration that can damage your foundation and insulation.

Landscape features should enhance your grading efforts. Keep planting beds slightly lower than surrounding grade and avoid creating barriers that trap water near your foundation. The goal is to allow water to flow away from your cabin on all sides.

Managing Roof Water Flow

Your roof collects a lot of water that must be directed away from your foundation. Without proper gutter systems and downspout extensions, roof runoff can saturate the soil near your foundation walls. This makes roof water management as important as underground protection.

Large roof overhangs provide your first line of defense by projecting water several feet away from your cabin naturally. Overhangs of 24-36 inches ensure melting snow and rainfall land far from the foundation, reducing the volume of water your drainage systems must handle. This traditional cabin design element combines aesthetic appeal with practical moisture protection.

Complete gutter systems capture the water that overhangs don’t eliminate. Properly sized gutters along all roof edges collect runoff and channel it to controlled discharge points. Clean gutters regularly to prevent overflow that dumps water directly beside your foundation.

| Component | Function | Key Specification |

|---|---|---|

| Roof Overhangs | Project water away from cabin walls | 24-36 inch extension minimum |

| Gutter Channels | Collect and direct roof runoff | 5-6 inch width for standard cabins |

| Downspout Extensions | Discharge water far from foundation | 6-10 feet from foundation walls |

| Splash Blocks | Prevent soil erosion at discharge points | Angled away from foundation |

Downspout extensions complete your water management system by carrying gutter discharge at least 6-10 feet away from your foundation. Flexible or rigid extensions both work effectively when positioned to maintain positive slope. Underground drain pipes offer a permanent solution that moves water even farther from your cabin.

The combination of roof overhangs, gutters, and extended downspouts prevents concentrated water flow that causes foundation problems. This integrated approach to water management protects your foundation waterproofing, drainage systems, and insulation from moisture damage. Every component works together to keep your cabin dry and structurally sound for generations.

Protecting Your Foundation from Pests and Rot

Insulation keeps your cabin warm or cool, but it’s not enough. Foundation pest control and managing moisture are key to stopping pests and rot. Even the best insulation can fail if termites or moisture damage wood. A good plan for pest prevention and wood rot prevention keeps your foundation strong for years.

Most pests and rot can be stopped with smart design and upkeep. Knowing how pests get in and what causes wood to rot helps you protect your foundation.

Termite Barriers and Protection

Termites are everywhere in the U.S., making termite protection a must. They can damage your home a lot before you see them. Foundation areas are at high risk because termites travel from soil to wood.

Metal termite shields are a good start. They block termites at the foundation and wall junction. Shields should go two inches beyond the foundation and angle down to stop termites from going under.

Chemical treatments around the foundation keep termites away. These treatments last 5-10 years and kill termites. Some use liquid, while others use bait systems.

Not all insulation is the same. Some foam has pesticides to stop termites. But regular foam can let termites through if not detailed right. Make sure to leave gaps for inspections.

Adding layers of protection helps defend against many threats. Regular checks are key—look for mud tubes, damaged wood, or termite wings near vents.

Rodent-Proofing Strategies

Rodents like mice and rats find insulated foundations perfect for nesting. They can damage insulation and leave health hazards.

Screening keeps rodents out. Use hardware cloth or metal mesh with small holes over foundation openings. Window screens won’t work because rodents can chew through them.

Insulated skirting around pier and post foundations needs screening too. This stops insects and rodents while keeping air flowing.

For crawl spaces, make sure vapor barriers cover foundation walls and seal well. Any big gaps let mice in. Use foam or metal to seal around pipes and install door sweeps.

| Protection Method | Best Application | Effectiveness | Maintenance Needs |

|---|---|---|---|

| Metal Termite Shields | Foundation-to-wall junction | High for detection | Annual inspection |

| Chemical Soil Treatment | Foundation perimeter | Very high for prevention | Reapply every 5-10 years |

| Hardware Cloth Screening | Vents and openings | Excellent for rodents | Check annually for damage |

| Borate-Treated Lumber | Any wood near foundation | High for termites and rot | Permanent protection |

Preventing Wood Rot and Decay

Wood rot is a big threat, where foundation meets wood. Moisture and wood are a bad mix for decay fungi. Logs with moisture content above 15% risk damage.

Start with the right materials. Use treated or rot-resistant wood near the ground. Pressure-treated wood lasts a long time against decay.

Keep foundation wood dry with good drainage. Slope the ground away from your cabin to keep water off. Use gutters to control water around the foundation.

Airflow is key to prevent moisture. Even with vapor barriers, crawl spaces need ventilation. Install vents and use mechanical systems to control humidity.

Regular checks are important. Look for soft spots, discoloration, or a musty smell. Use a moisture meter to check wood moisture. Fix moisture issues fast to stop decay.

Focus on areas where materials meet. Flashing at the foundation and wood junction stops water damage. Use metal or rubber flashing that covers foundation walls and under siding.

Pest prevention and wood rot prevention go hand in hand. Rotting wood attracts pests, and pest damage can cause more rot. A good plan protects against both with the right materials, moisture control, and regular checks.

Common Foundation Insulation Mistakes to Avoid

Learning from common insulation mistakes saves you from costly do-overs and frustrating repairs. Even well-intentioned cabin owners sometimes overlook critical details. These details compromise your foundation’s thermal performance and durability. Understanding these frequent errors helps you get things right the first time and protects your investment for years to come.

The good news is that most foundation insulation problems are entirely preventable. By recognizing these pitfalls before you start your project, you’ll avoid the headaches and expenses that come with fixing them later. Let’s look at the most common mistakes and how to steer clear of them.

Getting Vapor Barriers Wrong

Vapor barrier errors rank among the most frequent foundation insulation mistakes cabin owners make. Many people install vapor barriers on the wrong side of the insulation, creating conditions where moisture gets trapped instead of controlled. In heating climates, vapor barriers generally belong on the warm side of insulation—but foundation applications often work better with vapor retarders instead of complete vapor barriers.

Installing barriers with gaps, tears, or unsealed seams defeats their entire purpose. Moisture will find every opening and exploit it, leading to dampness inside your insulation and eventual structural problems. Take the time to overlap seams by at least six inches and seal them completely with appropriate tape or mastic.

Another common error involves forgetting vapor barriers altogether in crawl spaces. Some cabin builders assume that ventilation alone will handle moisture, but modern building science shows that ground vapor barriers are essential for controlling humidity. Use a heavy-duty polyethylene sheet rated at least 6 mils thick, and extend it up the foundation walls.

Here’s something many people don’t realize: the proper order matters tremendously. Waterproofing should always go on first, directly against the foundation, with insulation installed afterward. This sequence ensures that your waterproofing membrane can do its job effectively while the insulation stays dry and maintains its thermal performance.

Skipping the Permitting Process

Ignoring local building codes and the permitting process creates problems that extend far beyond your foundation. Building code compliance isn’t just bureaucratic red tape—these requirements exist to prevent structural failures, moisture problems, and energy waste. Codes are developed based on decades of building experience and local climate conditions.

Unpermitted work can seriously complicate insurance claims if you ever need to file one. Many insurance companies will deny claims for work that wasn’t properly permitted and inspected. Also, when you eventually sell your cabin, unpermitted foundation work can delay or derail the sale entirely.

Different regions have specific requirements for minimum R-values, frost depth protection, and foundation details. What works perfectly in Georgia might be completely inadequate in Minnesota. Before starting any foundation insulation project, check with your local building department to understand the requirements in your area.

Working with a building inspector isn’t your enemy—it’s your safeguard. Inspectors catch problems before they become expensive failures. They ensure your foundation insulation meets current standards for energy efficiency and structural integrity. Schedule inspections at the required stages and address any concerns promptly.

Selecting Inappropriate R-Values

Choosing wrong R-values is an insulation mistake that costs you either in wasted money or reduced comfort. Under-insulating is the most common problem, where cabin owners install the bare minimum to save on materials but sacrifice long-term energy savings and comfort. The few hundred dollars you save upfront translate into thousands in higher heating costs over the cabin’s lifetime.

On the flip side, over-insulating in mild climates occasionally happens when builders apply cold-climate standards where they’re not needed. In zones 1 and 2, installing R-30 foundation insulation provides minimal additional benefit compared to R-15, and the extra cost rarely pays for itself in energy savings.

Match your insulation levels to your specific climate zone and local energy costs. If you’re in zone 5 or higher, investing in higher R-values makes excellent financial sense. The climate zone recommendations we covered earlier provide solid starting points based on heating degree days and regional conditions.

| Climate Zone | Minimum R-Value | Recommended R-Value | Common Mistake |

|---|---|---|---|

| Zones 6-7 | R-15 | R-20 to R-25 | Stopping at R-10 |

| Zones 4-5 | R-10 | R-15 to R-20 | Using only R-5 |

| Zones 1-3 | R-5 | R-10 to R-15 | Over-insulating past R-20 |

Remember that insulation’s effectiveness also depends on proper installation. An R-20 insulation board installed with gaps and voids performs worse than a carefully installed R-15 system. Quality installation matters as much as the R-value you choose.

Neglecting Air Sealing Completely

Poor air sealing undermines even the best insulation job. Air leaks at rim joists, around penetrations, and at foundation-to-wall connections can reduce your insulation’s effectiveness by 30% or more. Insulation slows heat transfer through materials, but it does little to stop air movement carrying heat with it.

Many cabin builders focus exclusively on insulation and completely forget about air sealing foundation connections. The junction where your foundation meets the wall framing is very vulnerable. This area needs careful attention with spray foam, gaskets, or appropriate sealants to prevent air leakage.

Unsealed crawl space vents are another frequent oversight. If you’re creating a conditioned crawl space, those old foundation vents must be sealed permanently. Leaving them open allows outside air to undermine your insulation and introduce moisture. Use rigid foam board cut to fit snugly, sealed around all edges with spray foam.

Address penetrations methodically as part of your air sealing foundation strategy. Plumbing pipes, electrical conduits, and HVAC ducts all create pathways for air leakage. Seal each penetration with appropriate materials—spray foam for larger gaps, caulk for smaller ones. Work systematically around the entire foundation perimeter.

Here’s a practical tip: air sealing should happen before or in conjunction with insulation, never as an afterthought. Once insulation is in place, accessing areas that need sealing becomes difficult or impossible. Plan your air sealing strategy before you start installing insulation, and check off each area as you complete it.

One detail worth mentioning from real-world experience: metal flashing protecting above-grade exterior foam can get dinged up over the years if it’s not heavy gauge material. While there’s no perfect answer to protecting exposed foundation insulation, choosing durable materials and installing them carefully prevents unnecessary repairs down the road.

These common mistakes are surprisingly easy to make, even with good intentions. The key is recognizing them before they happen and taking the extra time to do things properly. Your foundation insulation represents a significant investment in your cabin’s comfort and efficiency—protecting that investment means avoiding these pitfalls from the start.

Maintaining Your Insulated Cabin Foundation

Regular foundation maintenance is key to protecting your investment. It prevents small problems from turning into big, costly repairs. A well-insulated foundation needs regular attention to keep performing well.

Foundation maintenance doesn’t require extensive technical knowledge or expensive equipment. With basic knowledge, you can catch problems early. This saves money and extends your insulation system’s life.

Foundation care is like a simple routine, not a burden. Spending a few hours on inspections each season can save thousands in repairs. Most cabin owners find it becomes second nature once they establish a routine.

Seasonal Inspection Checklist

Different seasons bring different challenges to your cabin’s foundation. A seasonal inspection routine helps address issues at the right time. Each season has specific concerns.

Spring inspections focus on winter damage. Check protective coatings and flashings for cracks or separation. Metal flashing protecting foam insulation can get damaged, which is common in high-snow areas.

Look for cracks in concrete or masonry that may have developed during cold months. Verify that all drainage systems are clear and functional after winter debris has accumulated. Spring is also the perfect time to check for signs of pest activity as rodents and insects become more active.

Summer maintenance centers on vegetation control and UV protection. Keep plants, shrubs, and trees at least two feet away from your foundation. Their roots can damage waterproofing membranes and create moisture problems.

Inspect gutters and downspouts to ensure they’re directing water away from the foundation properly. Check above-grade insulation protection for UV damage or physical wear. Protective coatings on exposed foam may need touch-ups every few years depending on sun exposure.

Fall preparation gets your foundation ready for winter. Clear all leaves and debris from drainage systems before they become clogged. Check for any gaps or openings that pests might use to seek winter shelter inside your cabin.

Verify that moisture barriers remain intact and properly sealed. This is your last chance before cold weather to make repairs that might be difficult once temperatures drop. Address any foundation problems you’ve been putting off.

Winter checks can be limited if snow coverage makes access difficult. When conditions allow, look for ice dams or excessive icicles that indicate heat loss through your foundation. Unusual heating costs during winter often signal insulation performance issues worth investigating.

| Season | Key Inspection Tasks | Common Issues to Address | Tools Needed |

|---|---|---|---|

| Spring | Check for winter damage, clear drainage systems, inspect protective flashings | Cracked coatings, damaged flashings, pest entry points, clogged drains | Flashlight, screwdriver, garden hose, caulk gun |

| Summer | Control vegetation, check UV protection, inspect gutters and downspouts | Overgrown plants, UV-damaged coatings, blocked gutters, soil grade changes | Pruning shears, ladder, protective coating materials, level |

| Fall | Clear debris, seal gaps, verify moisture barriers, prepare for winter | Leaf-clogged drains, pest entry gaps, worn vapor barriers, loose skirting | Leaf blower, foam sealant, vapor barrier tape, repair materials |

| Winter | Monitor for ice dams, check heating costs, look for excessive heat loss | Ice dams, unusual energy bills, condensation problems, frozen pipes | Binoculars, energy monitor, moisture meter, thermal camera (optional) |

Monitoring for Moisture Problems

Moisture monitoring is key to foundation maintenance. Water harms insulation and structural integrity. Catching moisture issues early prevents serious damage.

Learn to recognize the warning signs of moisture intrusion before they become major problems. Musty odors in basements or crawl spaces are often the first indicator that something isn’t right. Don’t ignore these smells—they signal moisture accumulation even if you can’t see it yet.

Visible mold or mildew on walls, floor joists, or insulation materials requires immediate attention. Efflorescence—those white crusty deposits on foundation walls—indicates water moving through concrete or masonry. These mineral deposits appear when water evaporates, leaving minerals behind.

Increased humidity levels inside your cabin can signal foundation moisture problems. Condensation appearing on walls, pipes, or windows during mild weather suggests humidity sources that shouldn’t be present. Wood components that feel soft or show discoloration indicate moisture content that’s too high.

Simple tools make moisture monitoring more accurate. Basic moisture meters cost less than fifty dollars and help detect problems before they become visible. These devices measure moisture content in wood and other materials with good accuracy.

Wood moisture content above 15 percent causes mildew, mold, and rot. Regular testing of floor joists, sill plates, and other wooden foundation components helps you catch problems early. Test the same locations during each seasonal inspection to track changes over time.

Rising heating costs without obvious explanation often indicate moisture compromising insulation performance. Wet insulation loses R-value dramatically, forcing your heating system to work harder. If you notice increased energy bills, moisture infiltration might be the culprit.

When to Call a Professional

Knowing when to tackle foundation problems yourself versus when to call an expert is important. Some situations definitely require professional assessment and repair. There’s no shame in recognizing when a job exceeds your skills or comfort level.

Significant foundation cracks—specifically those wider than a quarter inch or showing signs of movement—need professional evaluation. These could indicate structural issues that require engineering expertise. Don’t attempt to cover serious cracks with simple patching compounds.

Persistent moisture problems despite good drainage and proper grading suggest hidden issues. A professional can use thermal imaging, moisture mapping, and other diagnostic tools to identify sources you might miss. They can also recommend solutions beyond basic DIY approaches.

Extensive pest damage, such as from termites or carpenter ants, requires professional treatment and repair. These insects can compromise structural integrity in ways that aren’t immediately obvious. A pest control specialist combined with a foundation contractor ensures complete remediation.

Major insulation damage or significant gaps in your insulation system benefit from professional reinstallation. While minor repairs work for DIY maintenance, extensive damage often indicates underlying problems that need expert diagnosis. Professional foundation inspection provides peace of mind when you’re dealing with substantial issues.

Significant settling or structural movement in your foundation is always a professional concern. Doors that suddenly stick, new cracks in interior walls, or floors that become noticeably unlevel signal possible foundation movement. These situations require structural engineering assessment.

Call a professional anytime you’re simply not comfortable with the work involved. Your safety matters more than saving a few dollars on labor. Professionals carry insurance, have proper equipment, and understand building codes that affect foundation repairs.

Catching foundation problems early through regular inspection prevents small issues from becoming expensive disasters. Most cabin owners find that a simple seasonal routine combined with basic moisture monitoring keeps their insulated foundation performing well for decades. The time invested in preventative care pays dividends in comfort, energy savings, and long-term structural protection.

Building a Warm and Protected Cabin for Generations

Insulating your cabin foundation is a smart choice. It’s more than just saving on heating costs this winter. You’re creating a lasting home for your family.

Timber is durable and keeps warmth in. With the right foundation care, your log cabin can withstand harsh weather. It’s all about choosing the right insulation for your area and using materials that resist moisture.

The initial cost might seem high. But the benefits are huge: lower energy bills, comfort all year, protection from moisture, fewer pests, and a longer-lasting cabin. Your cabin stays valuable and cozy for years.

Building sustainably starts with a strong foundation. Whether you’re building from scratch, updating an old cabin, or getting your first inspection, every step counts. Small changes can make a big difference over time.

Your cabin needs a solid, safe foundation. Start protecting your investment today. Enjoy a warm, efficient home that holds memories and keeps you cozy for years to come.