Welcome to our guide on choosing the right structure for your property. If you’re thinking about adding extra space, you face many choices. This article will help you understand if a modern factory-built unit is the best fit for your needs.

These structures have come a long way. They are no longer just simple sheds. Today, they serve as versatile living areas like home offices or cozy guest houses.

Our goal is to give you a clear, honest look at the benefits and drawbacks. We want you to make a smart choice for your situation. Knowing the full picture before you invest is very important.

We will explore costs, build time, and how much you can customize your space. We’ll also look at quality and long-term value. Every property owner has unique needs, so what works for one home might not suit another.

This analysis is based on real-world facts, not just sales talk. The options available now offer more design choices and better materials than ever before. For a deeper comparison, see how these units stack up against traditional building.

Exploring the World of Prefab Cabins

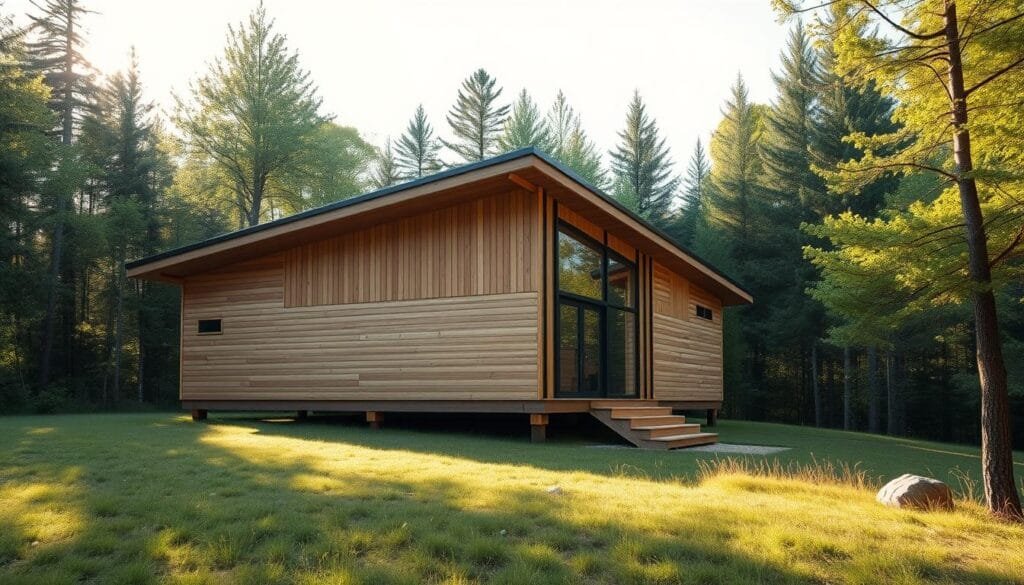

The world of off-site construction offers innovative solutions for expanding your living areas. These factory-built structures represent a modern alternative to traditional building methods.

What Are Prefab Cabins?

Prefabricated structures are built in a controlled factory environment. Components are manufactured to exact specifications before transportation to your property.

This construction process differs significantly from traditional on-site building. Factory settings allow for better quality control and protection from weather delays.

There are three main types of these homes available today. Manufactured units come in sections assembled by professionals. Kit versions offer simpler designs for DIY assembly. Modular options provide the most customization with personalized floor plans.

Evolution and Modern Trends

These structures have evolved from basic storage sheds into sophisticated living spaces. Modern prefab homes now serve as offices, guest houses, and entertainment areas.

Current trends focus on sustainability and smart technology. Many new designs incorporate energy-efficient features and minimalist aesthetics. Multi-purpose spaces adapt to changing homeowner needs.

The controlled factory environment ensures precision during assembly. This approach leads to tighter seams and superior insulation. For a deeper look at these innovative structures, explore our complete backyard transformation guide.

Prefab Cabins Pros and Cons

Before committing to any building project, smart homeowners weigh the advantages against the limitations. Factory-built structures offer distinct benefits that make them attractive for many situations.

Key Benefits of Prefab Cabin Construction

The speed of assembly stands out as a major advantage. Factory work continues regardless of weather conditions. Multiple construction phases happen simultaneously.

Cost effectiveness comes from efficient processes. Bulk material purchasing and reduced labor expenses lower the overall price. Factory settings ensure consistent quality control through standardized procedures.

Environmental benefits include reduced waste and better energy performance. Precise construction creates tight seams for superior insulation. Many manufacturers use sustainable materials in their designs.

Potential Drawbacks and Considerations

Transportation expenses can add thousands to your final cost. The structure must be delivered from factory to your site. This requires specialized equipment and careful planning.

Site preparation demands proper foundation work before delivery. Your land needs leveling and utility connections arranged. These upfront requirements often surprise first-time buyers.

Hidden costs include permits, inspections, and utility hookups. The base price doesn’t cover these essential elements. Financing can be challenging with some lenders unfamiliar with this construction method.

| Feature | Factory-Built | Traditional Construction | Key Difference |

|---|---|---|---|

| Construction Time | 4-8 weeks | 3-6 months | Weather-independent factory work |

| Cost Control | Fixed factory pricing | Variable labor/material costs | Bulk purchasing advantages |

| Quality Consistency | Standardized processes | Site-dependent craftsmanship | Controlled environment benefits |

| Waste Generation | 10-15% less | Higher on-site waste | Precision cutting reduces excess |

Environmental and Efficiency Impacts

These structures typically offer better energy performance. Tight construction prevents air leaks and improves insulation. This leads to lower utility bills over time.

The manufacturing process generates less waste than traditional building. Leftover materials can be reused in other projects. This makes factory construction more sustainable overall.

Understanding both the benefits and limitations helps you make the right choice. Consider your budget, timeline, and specific needs before deciding.

Understanding the Construction Process and Costs

Getting your new structure built involves two main paths: factory or on-site construction. Knowing how each method works helps you plan your project better.

The factory approach builds components indoors. This controlled setting protects materials from weather. Work continues without rain or snow delays.

Traditional building happens entirely on your property. Crews work through all seasons outdoors. This can lead to unexpected weather-related stoppages.

Factory-Built vs. Traditional On-Site Construction

Factory construction offers a significant time advantage. Multiple phases happen at once. While crews prepare your land, the structure gets built at the plant.

This parallel workflow slashes project timelines. Some homes are ready in weeks instead of months. You get to use your new space much faster.

Cost control is another major benefit. Factory settings use fixed labor rates and bulk material purchases. This creates more predictable pricing for your budget.

Additional Expenses: Site Preparation and Utility Hookups

Your land needs proper site preparation before delivery. This includes leveling the ground and soil testing. These steps ensure a stable foundation for your house.

Utility connections represent another cost category. You’ll need electrical, water, and sewer hookups. These expenses add significantly to your total project costs.

Proper planning prevents budget surprises. Remember to factor in these additional requirements. For more financial insights, review this guide on home financing considerations.

Customization, Design, and Usage Options

Your property’s potential expands dramatically when you explore the flexible design possibilities of modern factory-built structures. These units are far from basic boxes. They offer a wide range of solutions tailored to your specific lifestyle.

Whether you need a quiet place to work or a cozy spot for guests, these structures can be adapted perfectly. The key is matching the design to your exact needs.

Adapting Prefab Cabins for Various Needs

Think of your new structure as a versatile addition to your property. It can serve many purposes beyond simple storage.

For a dedicated home office, ensure it has proper insulation and electrical outlets. This creates a productive area separate from your main living space. A creative studio might need large windows for natural light. A guest house requires plumbing for a comfortable stay.

The available options are impressive. You can choose from different sizes, exterior finishes, and interior layouts. This lets the structure blend seamlessly with your existing home.

- Home Office: A quiet, dedicated work area away from household distractions.

- Creative Studio: A personalized space for hobbies, art, or music.

- Guest House/ADU: Private lodging for visitors or potential rental income.

Always consider practical needs like climate control and local building codes. This planning ensures your new space is functional and compliant for years to come.

Quality, Durability, and Performance Overview

The lasting value of any building project depends heavily on construction quality and material durability. Modern factory-built structures have evolved significantly in these areas.

Reputable manufacturers now produce homes that match traditional building standards. The controlled factory environment actually enhances quality control through standardized processes.

Inspections, Materials, and Long-Term Maintenance

Factory construction involves multiple inspection stages throughout the building process. These quality checks ensure every component meets strict standards before shipment.

Premium manufacturers use grade lumber and engineered components for superior durability. Proper maintenance involves regular roof inspections and exterior surface care.

These homes can withstand natural elements when constructed correctly. Many companies offer substantial warranties demonstrating confidence in their product quality.

Energy Efficiency and Sustainable Building Practices

Factory precision creates tighter construction with fewer air leaks. This results in better insulation and reduced energy costs for homeowners.

Sustainable practices include reduced material waste and eco-friendly material choices. The manufacturing process allows for precise cutting and material reuse.

Energy efficiency becomes a significant long-term benefit. Advanced window systems and proper insulation contribute to lower utility bills.

Comparing Prefab Cabins to Traditional Construction Methods

When choosing between modern and conventional building approaches, understanding the core differences in process and outcome is crucial. This side-by-side look goes beyond surface claims.

It helps you see which method aligns with your budget, timeline, and vision for your property.

Cost Control and Time Efficiency

Speed is a major advantage of factory-built structures. A traditional house can take six to twelve months to complete on-site.

In contrast, a modern prefab home often finishes in just six to twelve weeks after site prep. This time savings comes from the controlled factory environment.

Work continues uninterrupted by weather. This parallel workflow slashes project timelines significantly.

Cost predictability is another key benefit. Factory settings use fixed labor rates and bulk material purchases.

This leads to more stable pricing compared to variable on-site construction expenses. Reduced material waste also helps control the final cost.

For a deeper financial analysis, see this detailed comparison of prefabricated homes vs traditional.

Customization Options and Quality Control

Many people think traditional construction offers unlimited design freedom. While true in theory, modern prefab homes provide extensive options.

Reputable companies offer various layouts and finishes. Some homeowners find these structured choices easier to manage.

Quality assurance differs greatly between methods. The factory allows for standardized inspections at every stage.

This controlled process often results in more consistent quality. On-site building depends heavily on individual crew skill and weather conditions.

The final assembly of a factory-built house relies on precise, pre-measured components. This can mean less on-site flexibility but greater consistency in the final build.

Final Thoughts on Your Prefab Cabin Decision

As you weigh your options for adding functional space to your property, remember these key insights. Factory-built structures offer excellent solutions when chosen thoughtfully. They can serve as home offices, guest houses, or creative studios that add real value.

Honest budget planning is crucial. Account for all expenses beyond the base cost. This includes land preparation, utility connections, and transportation. Research local building codes before purchasing. Choose a reputable manufacturer with quality standards and good warranties.

Carefully assess your specific needs to select the right size and features. With proper planning and realistic budgeting, these homes can transform your property into a more functional and enjoyable space for years to come.